INGCACISO YEMVELISO

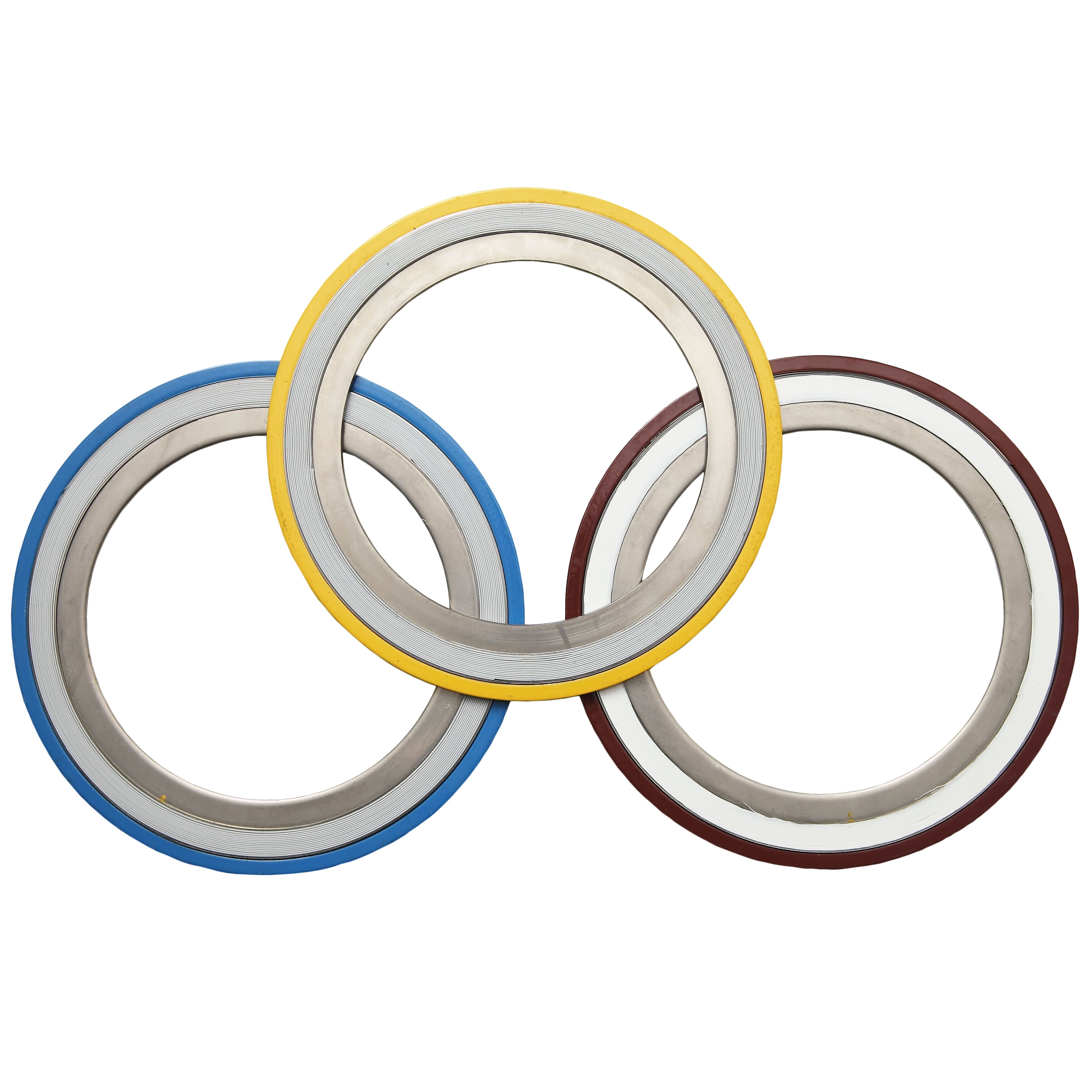

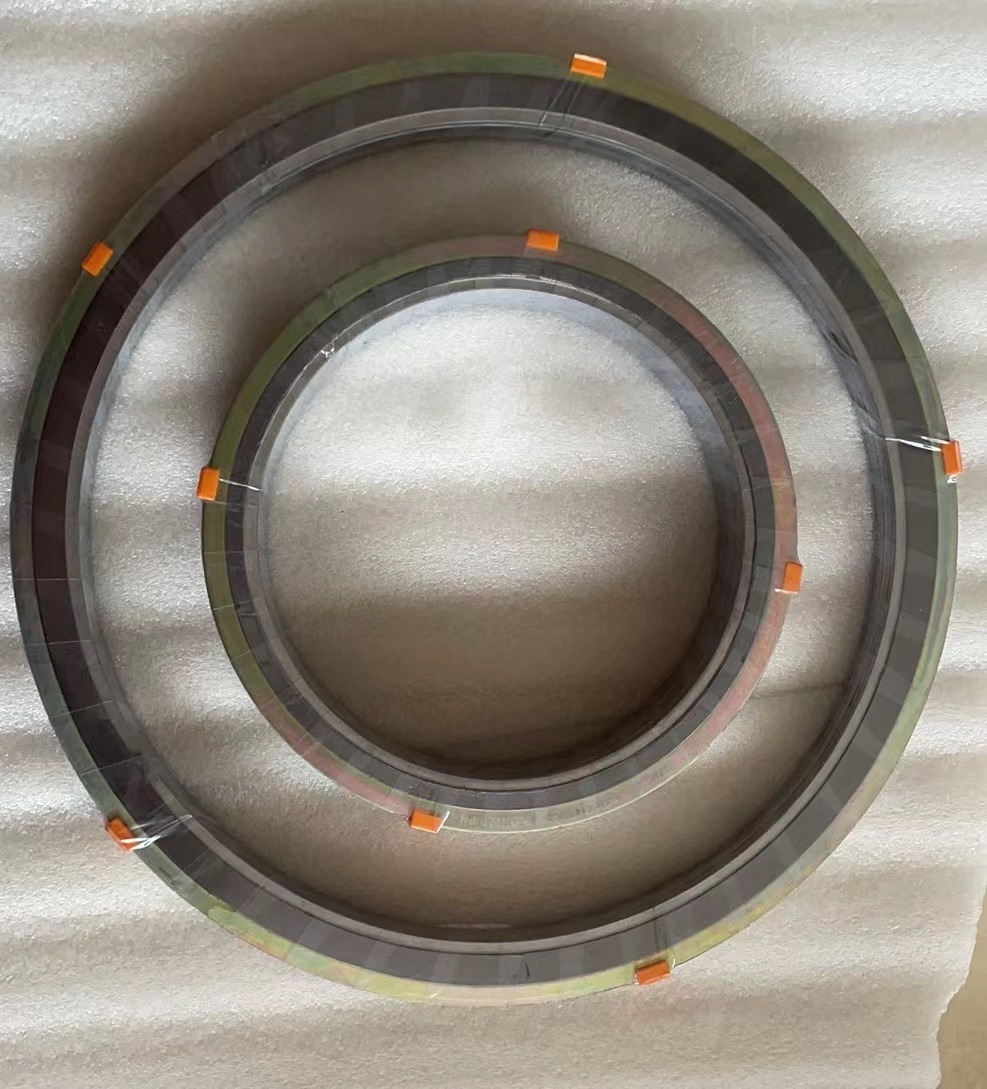

Iigaskets zeFlange

Iigasket zeflange zahlulwe zaba ziigaskithi zerabha, iigaskets zegraphite, kunye neemetal gaskets spiral (uhlobo olusisiseko).Basebenzisa umgangatho kunye

izinto ezigqitheneyo kunye nenxeba elijikelezayo, kwaye ibhendi yentsimbi igxininiswe ngokudibanisa amabala ekuqaleni nasekupheleni.Yalo

umsebenzi kukudlala indima yokutywina embindini weeflange ezimbini.

Ukusebenza

Ukusebenza: ubushushu obuphezulu, uxinzelelo oluphezulu, ukunganyangeki komhlwa, isantya esilungileyo soxinzelelo kunye nesantya sokubuyela kwakhona.Isicelo: Ukutywinwa

iinxalenye zemibhobho, iivalvu, iimpompo, imingxunya, iinqanawa zoxinzelelo kunye nezixhobo zokutshintshiselana kobushushu kwiindawo ezidityanisiweyo zepetroleum, iikhemikhali, amandla ombane, isinyithi, ukwakhiwa kweenqanawa, ukwenza iphepha, iyeza, njl njl. zizinto ezifanelekileyo zokutywina ezimile.

kunye noxinzelelo oluphezulu lwe-steam, i-oyile, ioli kunye negesi, i-solvent, i-oyile yomzimba wamalahle ashushu, njl.

IIPARAMETHA ZEMVELISO

| Izinto zokugcwalisa | IAsbestos | Igraphite ethambileyo (FG) | I-Polytetrafluoroethylene(PTFE) |

| Ibhanti yentsimbi | I-SUS 304 | SUS 316 | SUS 316L |

| Umsesane wangaphakathi | Intsimbi yeCarbon | I-SUS 304 | SUS 316 |

| Izinto zeRingi yangaphandle | Intsimbi yeCarbon | I-SUS 304 | SUS 316 |

| Ubushushu (°C) | -150 ~ 450 | -200~550 | 240~260 |

| Obona xinzelelo luphezulu lokusebenza (kg/cm2) | 100 | 250 | 100 |

IIFOTO ENGCACILEYO

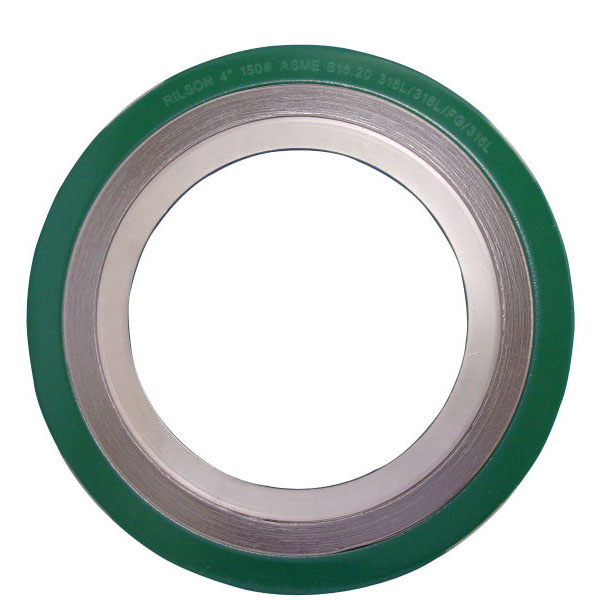

1. ASME B16.20 ngokomzobo wabathengi

2. 150#,300#,600#,900#1500#,2500#, njl.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Ngeflange kumbhobho okanye enye

UKUPAKISHA & UKUTHUMELA

1. Ipakishwe nge-plywood case okanye ipalethi yeplywood ngokwe-ISPM15

2. siya kubeka uluhlu lokupakisha kwiphakheji nganye

3. siya kubeka iimpawu zokuthumela kwiphakheji nganye.Amagama okumakisha akwisicelo sakho.

4. Zonke izinto zepakethe yeenkuni azifuzi

NGATHI

Sineminyaka engaphezulu kwe-20+ yamava asebenzayo kwi-Arhente

Ngaphezulu kweminyaka engama-20 yamava emveliso.Iimveliso esinokuzinika umbhobho wentsimbi, izixhobo zombhobho we-bw, izixhobo ezifakelweyo, iiflange ezibunjiweyo, iivalvu zoshishino.Iibholts & Nuts, kunye neegaskets.Izinto eziphathekayo zinokuba yintsimbi ye-carbon, insimbi engenasici, i-Cr-Mo insimbi ye-alloy, i-inconel, i-incoloy alloy, i-carbon steel steel, kunye nokunye.Singathanda ukunika ipakethe epheleleyo yeeprojekthi zakho, ukukunceda wonge iindleko kwaye kulula ngakumbi ukuzingenisa.

FAQ

1. Yintoni insimbi engenasici yegraphite filler?

I-Stainless Steel Graphite Packing yimpahla yokupakisha okanye yokutywina esetyenziselwa ukuthintela ukuvuza kwizicelo ezibandakanya ukushisa okuphezulu kunye noxinzelelo.Iqulethwe ngocingo olulukiweyo lwensimbi engenasici kunye negraphite efakiweyo yokumelana nobushushu kunye nokuhambelana kweekhemikhali.

2. Ziphi iifilisi ze-graphite zensimbi ezingenasici ezisetyenziswa ngokuqhelekileyo?

Iifayili zegraphite zensimbi ezingenasici zisetyenziswa ngokuqhelekileyo kumashishini ahlukeneyo kubandakanya ukusetyenzwa kweekhemikhali, i-petrochemical, i-oyile kunye negesi, ukuveliswa kwamandla, i-pulp kunye nephepha, kunye nokunye.Ilungele usetyenziso olubandakanya ulwelo olufana neeasidi, izinyibilikisi, umphunga kunye nezinye izinto ezidliwayo.

3. Ziziphi iingenelo zokuzalisa i-graphite yensimbi engenasici?

Ezinye zeenzuzo zokupakisha i-graphite yensimbi engenasici ziquka ukumelana nobushushu obuphezulu, ukuchasana kweekhemikhali okugqwesileyo, i-coefficient ephantsi ye-friction, i-conductivity efanelekileyo ye-thermal kunye neempawu eziphezulu zokutywinwa.Inokuphatha i-rpm ephezulu kunye nezantya ze-shaft ngaphandle kokuphazamisa ukusebenza kwayo.

4. Indlela yokufaka i-graphite yensimbi engenasici?

Ukufakela ukupakisha i-graphite yensimbi engenasici, susa ukupakisha endala kwaye uhlambulule ibhokisi yokucoca ngokucokisekileyo.Sika izinto ezintsha zokupakisha ubude obufunwayo kwaye uyifake kwibhokisi yokupakisha ngokwemiyalelo yomenzi.Sebenzisa i-gland yokupakisha ukuze ucinezele ngokulinganayo ukupakisha kwaye ukhusele i-gland yokupakisha ukukhusela ukuvuza.

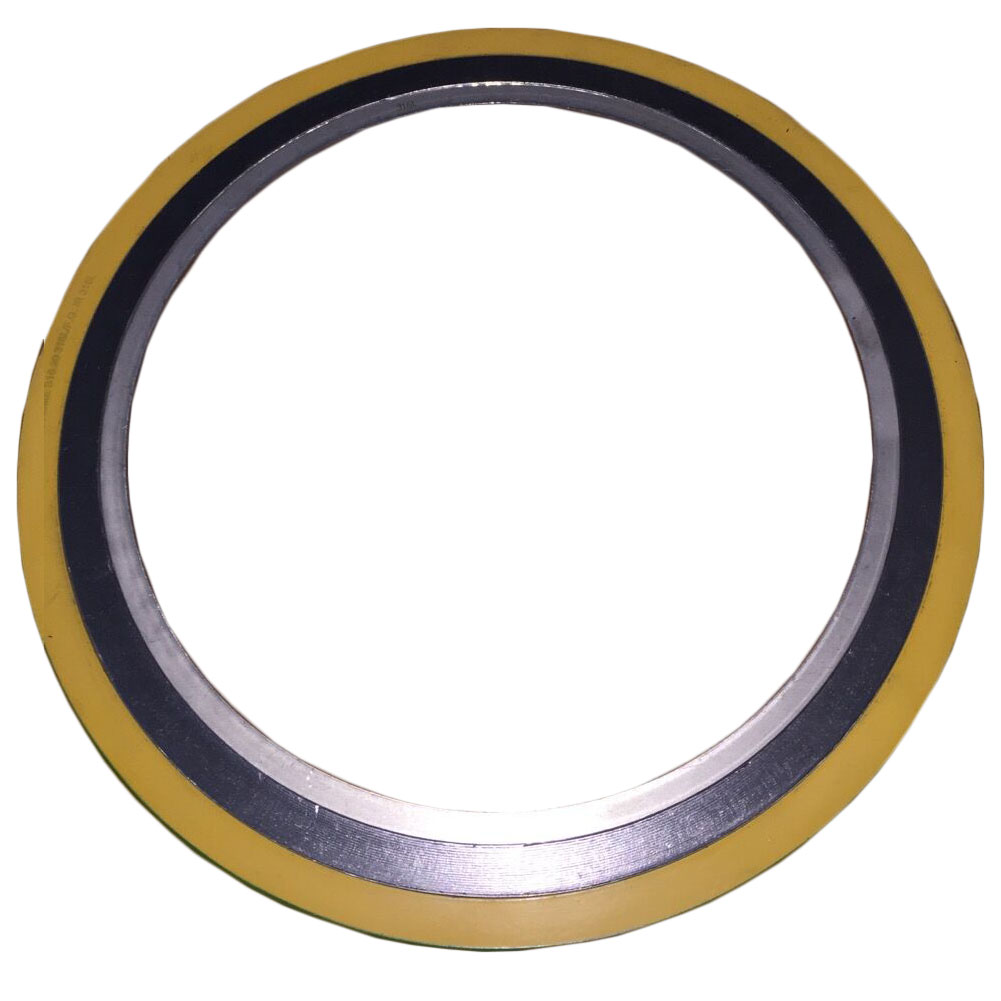

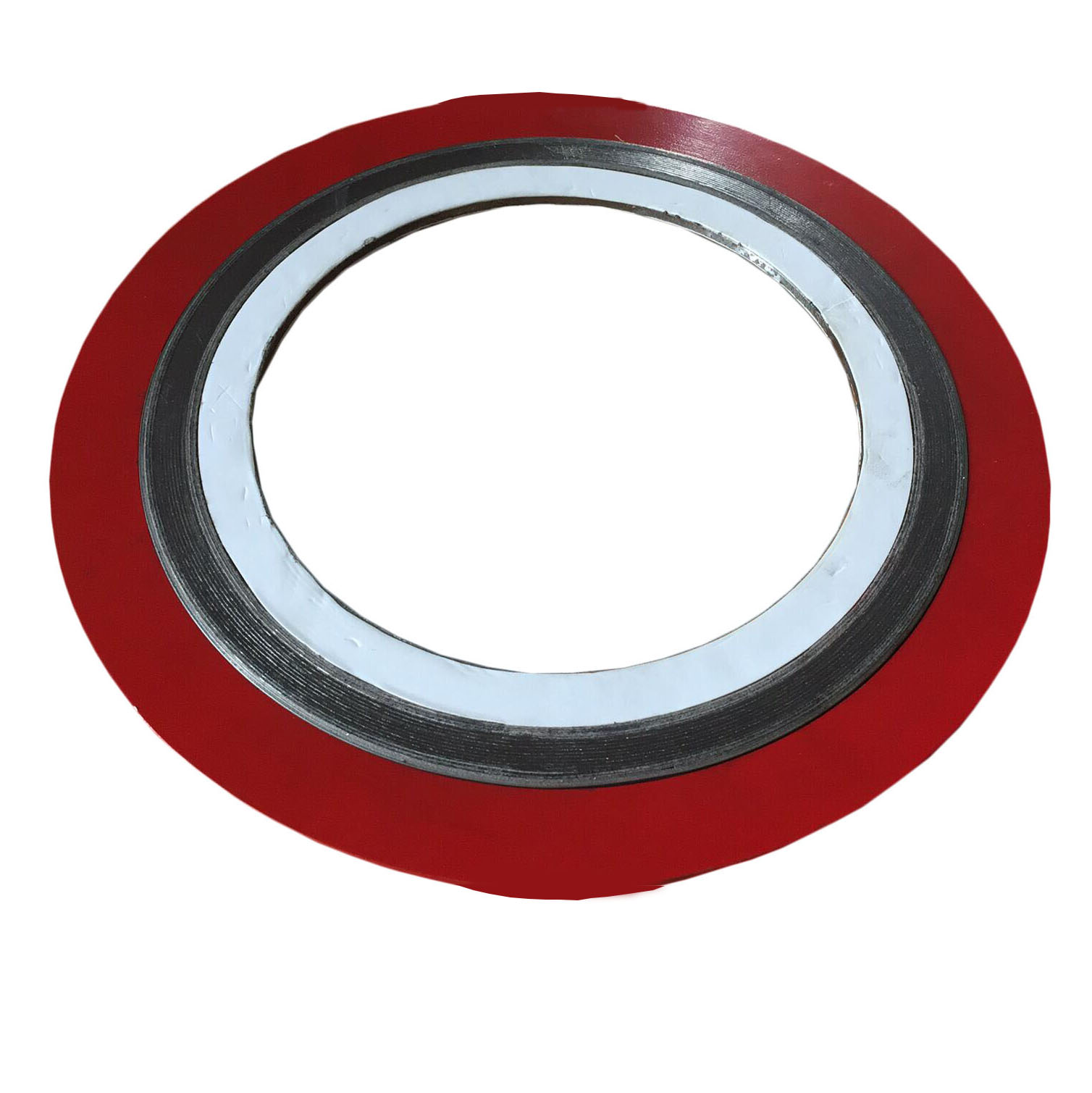

5. Yintoni i-spiral wound gasket?

Igaskithi yenxeba elijikelezayo yigasket ene-semi-metallic equlathe umaleko otshintshanayo wesinyithi kunye nemathiriyeli yokuzalisa (idla ngokuba yigraphite okanye i-PTFE).Ezi gaskets zenzelwe ukubonelela ngesisombululo esiqinileyo nesithembekileyo sokutywinwa koqhagamshelo lweflange oluphantsi kobushushu obuphezulu, uxinzelelo kunye nemidiya eyahlukeneyo.

6. Zidla ngokusetyenziswa phi iigaskets zamanxeba ajikelezayo?

I-Spiral wound gaskets idla ngokusetyenziswa kumashishini afana nokusetyenzwa kweekhemikhali, i-oyile negesi, iindawo zokucokisa, ukuvelisa umbane kunye nemibhobho.Zikulungele usetyenziso olubandakanya umphunga, ii-hydrocarbons, iiasidi kunye nolunye ulwelo oludlekayo.

7. Zeziphi iingenelo zeegasthi zamanxeba ajiyileyo?

Ezinye zezibonelelo ze-spiral wound gaskets ziquka ukuxhathisa kumaqondo obushushu aphezulu kunye noxinzelelo, ukunwebeka okugqwesileyo, ukukwazi ukutywina okugqwesileyo, ukuqhelana nezitenxo zeflange, kunye nokuhambelana okugqwesileyo kweekhemikhali.Banokumelana nokuhamba ngebhayisikile eshushu kwaye bagcine ingqibelelo yetywina.

8. Indlela yokukhetha i-gasket yenxeba elijikelezayo elifanelekileyo?

Ukukhetha igasket yenxeba elifanelekileyo elijikelezayo, qwalasela izinto ezifana nobushushu bokusebenza kunye noxinzelelo, uhlobo lolwelo, ukugqiba umphezulu weflange, ubungakanani beflange, kunye nobukho bayo nayiphi na imithombo yeendaba eyonakalisayo.Ukubonisana nomthengisi we-gasket okanye umenzi kunokunceda ukugqiba i-gasket engcono kakhulu yesicelo.

9. Indlela yokufaka i-spiral inxeba gasket?

Ukufakela i-gasket yenxeba elijikelezayo, qinisekisa ukuba ubuso be-flange bucocekile kwaye abunayo nayiphi na inkunkuma okanye izinto ezindala ze-gasket.Misa iwasha kwiflange kwaye ulungelelanise imingxuma yebholithi.Faka isicelo kunye noxinzelelo xa uqinisa iibholithi ukuqinisekisa nokuba uxinzelelo kwi-gasket.Landela ulandelelwano olucetyiswayo lokuqinisa kunye namaxabiso etorque anikezelwe ngumenzi wegasket.

10. Ingaba iigaskets zenxeba elijikelezayo zingaphinda zisetyenziswe?

Nangona ii-gaskets zamanxeba ajikelezayo zinokuphinda zisetyenziswe kwezinye iimeko, kuyacetyiswa ngokubanzi ukuba endaweni yazo kufakwe iigaskets ezintsha ukuqinisekisa ukusebenza kokutywina.Ukusebenzisa kwakhona iigaskets kunokubangela ukuthotywa kokusebenza, ukulahleka koxinzelelo, kunye nokuvuza okunokwenzeka.Ukuhlolwa rhoqo kunye nezenzo zokulondoloza kufuneka zilandelwe ukuchonga ngokukhawuleza kunye nokutshintsha iigaskets ezigugileyo.

-

A105 150lb Dn150 carbon steel welding isiliphu kwi f...

-

orifice flange WN 4″ 900# RF A105 ezimbini gr...

-

Umenzi okhethekileyo owenza uxinzelelo oluphezulu ...

-

Screw BSP DIN PN 10/16 carbon steel A105 flange...

-

WN ANSI B16.36 orifice weld intamo flange nge ja...

-

I-ANSI DIN Yenziwe iKlasi150 yeStainless Steel Slip o...