INGCACISO YEMVELISO

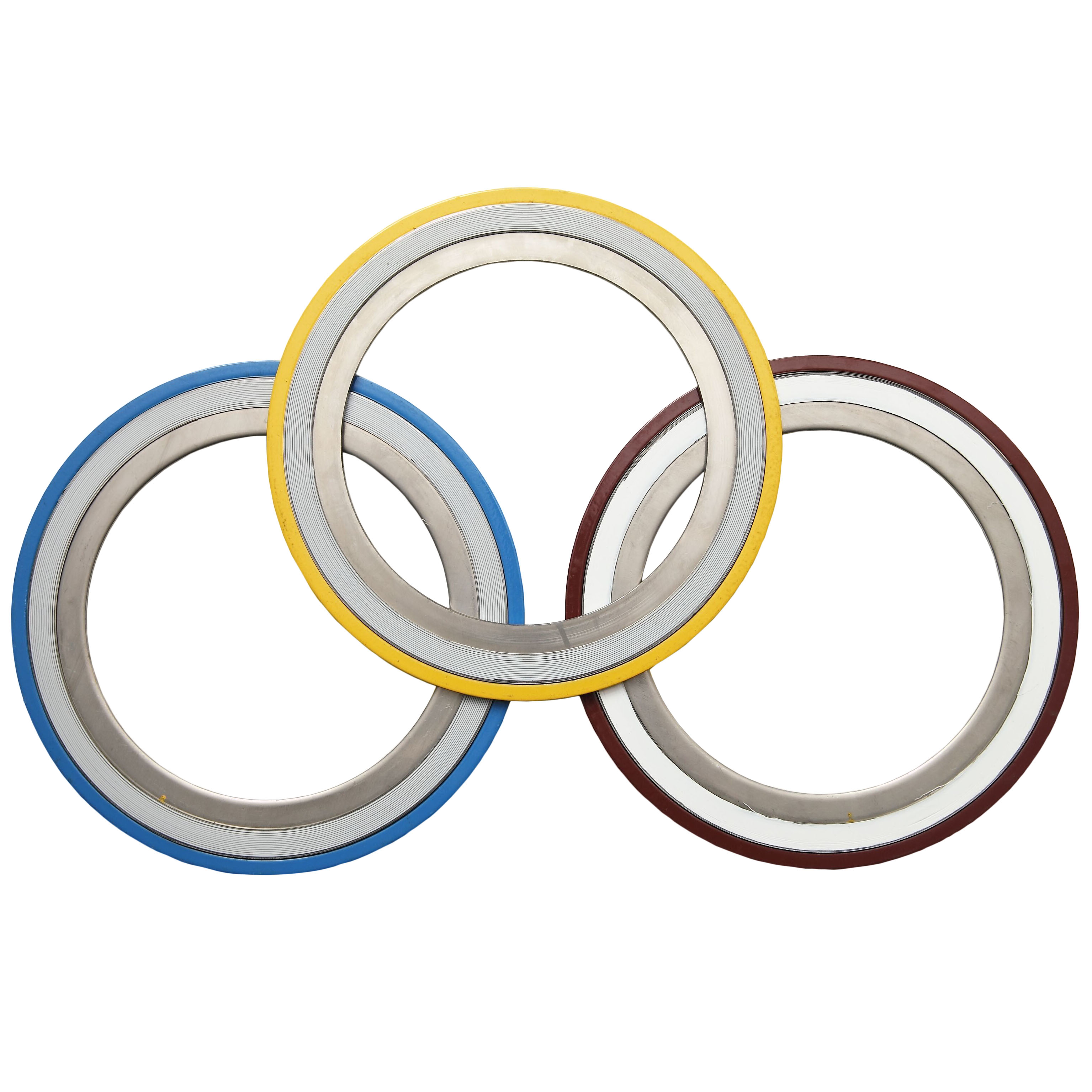

Iigasket zeFlange

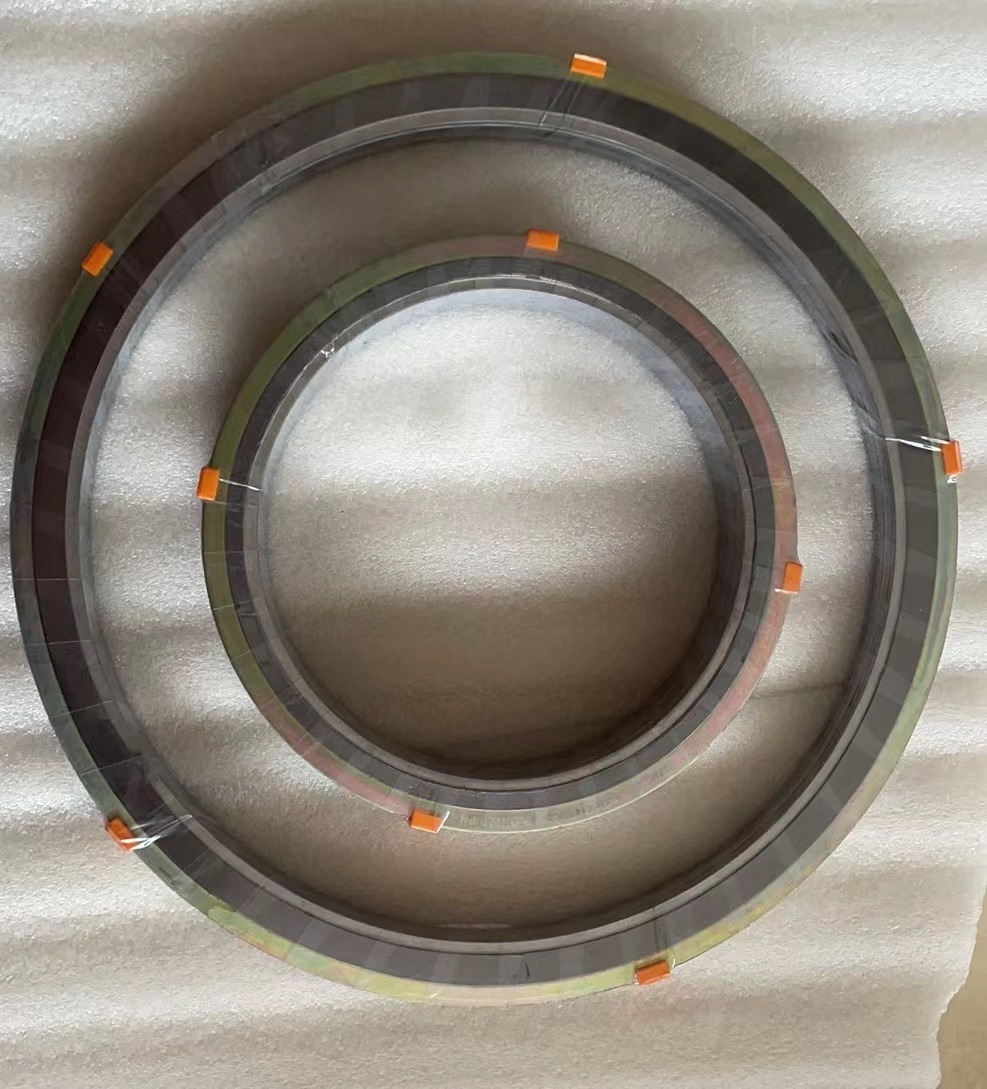

Iigasket zeFlange zahlulwe zibe ziigasket zerabha, iigasket zegrafiti, kunye neegasket zesinyithi ezijikelezayo (uhlobo olusisiseko). Zisebenzisa imigangatho eqhelekileyo kunye

Izinto ezisetyenzisiweyo zigqunywe kwaye ziboshwe ngendlela ejikelezayo, kwaye ibhendi yesinyithi iqiniswe ngokuwelda kwindawo ethile ekuqaleni nasekupheleni.

Umsebenzi kukudlala indima yokutywina embindini weeflange ezimbini.

Ukusebenza

Ukusebenza: ubushushu obuphezulu, uxinzelelo oluphezulu, ukumelana nokugqwala, izinga lokucinezelwa elihle kunye nezinga lokubuya kwakhona.

Iindawo zemibhobho, iivalvu, iimpompo, imingxunya yokukhupha amanzi, izitya zoxinzelelo kunye nezixhobo zokutshintshiselana nobushushu kwiindawo ezidityanisiweyo zepetroleum, iikhemikhali, amandla ombane, isinyithi, ukwakhiwa kweenqanawa, ukwenza amaphepha, amayeza, njl.njl. zezona zinto zifanelekileyo zokutywina ezingashukumiyo.

kunye nomphunga oxinzelelweyo ophezulu, ioyile, ioyile negesi, isinyibilikisi, ioyile yomzimba yamalahle ashushu, njl.

IIPARAMETHA ZEMVELISO

| Izixhobo zokugcwalisa | I-Asbestos | Igrafayithi eguquguqukayo (FG) | I-Polytetrafluoroethylene (PTFE) |

| Ibhanti yentsimbi | I-SUS 304 | I-SUS 316 | I-SUS 316L |

| Indandatho Yangaphakathi | Intsimbi yeCarbon | I-SUS 304 | I-SUS 316 |

| Izixhobo zeRing yangaphandle | Intsimbi yeCarbon | I-SUS 304 | I-SUS 316 |

| Ubushushu (°C) | -150~450 | -200~550 | 240~260 |

| Uxinzelelo oluphezulu lokusebenza (kg/cm2) | 100 | 250 | 100 |

IIFOWUNI EZINIKA INKCAZELO

1. I-ASME B16.20 ngokomzobo wabathengi

2. 150#,300#,600#,900#1500#,2500#,njl.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Yeflange kumbhobho okanye kwenye indawo

UKUPAKISHA NOKUTHUMELA

1. Ipakishwe ngebhokisi yeplywood okanye ipallet yeplywood ngokwe-ISPM15

2. siza kubeka uluhlu lokupakisha kwiphakheji nganye

3. Siza kubeka iimpawu zokuthumela kwiphakheji nganye. Amagama eempawu akwisicelo sakho.

4. Zonke izinto zokupakisha iinkuni azinazo izibulali-zinambuzane

NGATHI

Sinamava okusebenza angaphezu kweminyaka engama-20 kwi-Arhente

Amava emveliso angaphezulu kweminyaka engama-20. Iimveliso esinokuzibonelela ngepayipi yentsimbi, izixhobo zepayipi ye-bw, izixhobo ezifakelweyo, iiflange ezifakelweyo, iivalvu zemizi-mveliso. Iibholiti neenati, kunye neegasket. Izixhobo zinokuba yintsimbi yekhabhoni, intsimbi engatyiwayo, intsimbi ye-Cr-Mo alloy, i-inconel, i-incoloy alloy, intsimbi yekhabhoni enobushushu obuphantsi, njalo njalo. Singathanda ukukunika iphakheji epheleleyo yeeprojekthi zakho, ukukunceda wonge iindleko kwaye kube lula ukuzingenisa.

FAQ

1. Yintoni i-graphite filler yentsimbi engagqwaliyo?

I-Stainless Steel Graphite Packing yinto yokupakisha okanye yokutywina esetyenziselwa ukuthintela ukuvuza kwiindawo ezisebenzisa amaqondo obushushu aphezulu kunye noxinzelelo. Yenziwe ngocingo lwentsimbi engagqwaliyo olulukiweyo kunye ne-graphite efakwe emanzini ukuze ikwazi ukumelana nobushushu kakuhle kwaye ihambelane neekhemikhali.

2. Zisetyenziswa phi ii-grafiti fillers zentsimbi engagqwaliyo?

Izizalisi zegrafiti zentsimbi engagqwaliyo zisetyenziswa kakhulu kumashishini ahlukeneyo kuquka ukucubungula iikhemikhali, i-petrochemical, ioyile negesi, ukuveliswa kwamandla, i-pulp nephepha, nokunye. Ifanelekile ukusetyenziswa kwezinto ezifana nee-asidi, izinyibilikisi, umphunga kunye nezinye izinto ezibangela ukubola.

3. Ziziphi iingenelo ze-stainless steel graphite filler?

Ezinye zeenzuzo zokupakisha i-graphite yentsimbi engagqwaliyo ziquka ukumelana nobushushu obuphezulu, ukumelana neekhemikhali okugqwesileyo, i-coefficient ephantsi yokungqubana, ukuqhuba kakuhle kobushushu kunye neempawu zokuvala eziphezulu. Ingakwazi nokusingatha isantya esiphezulu se-rpm kunye ne-shaft ngaphandle kokuphazamisa ukusebenza kwayo.

4. Uyifaka njani i-stainless steel graphite packing?

Ukuze ufake i-graphite yentsimbi engagqwaliyo, susa i-packing endala uze ucoce ibhokisi yokuzalisa kakuhle. Sika izinto ezintsha zokupakisha zibe nobude obufunekayo uze uzifake kwibhokisi yokuzalisa ngokwemiyalelo yomenzi. Sebenzisa i-packing gland ukuze ucinezele ngokulinganayo i-packing kwaye uqinise i-packing gland ukuze uthintele ukuvuza.

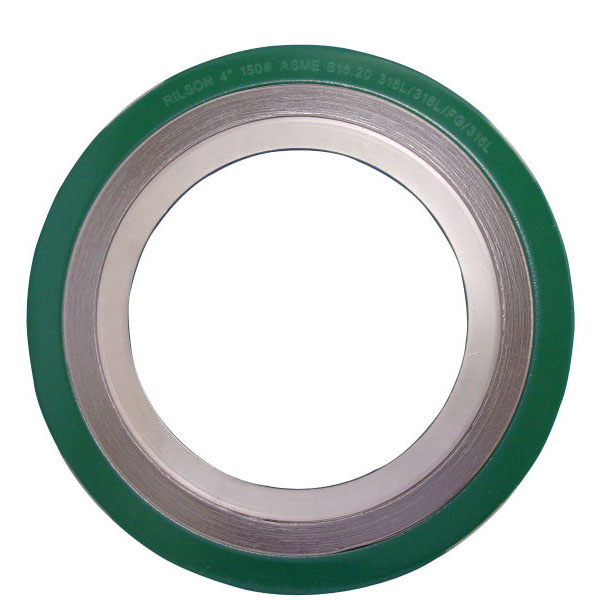

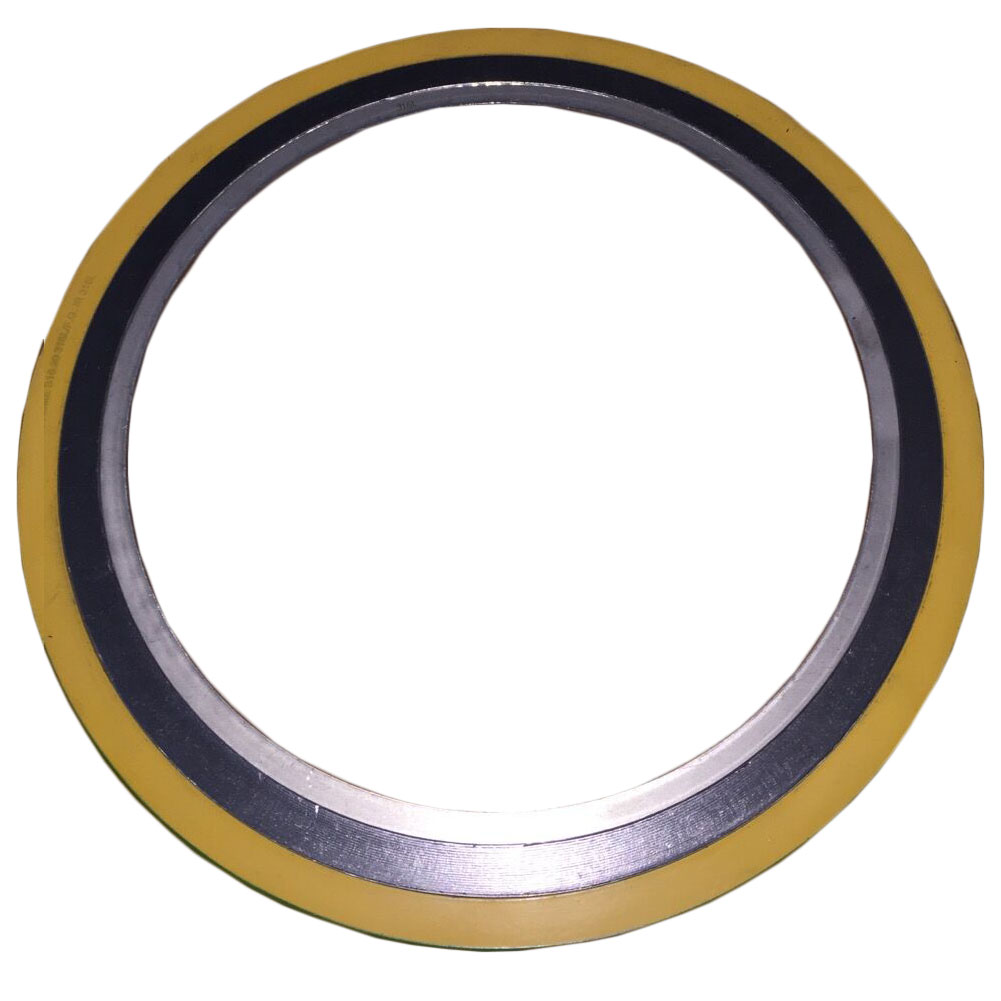

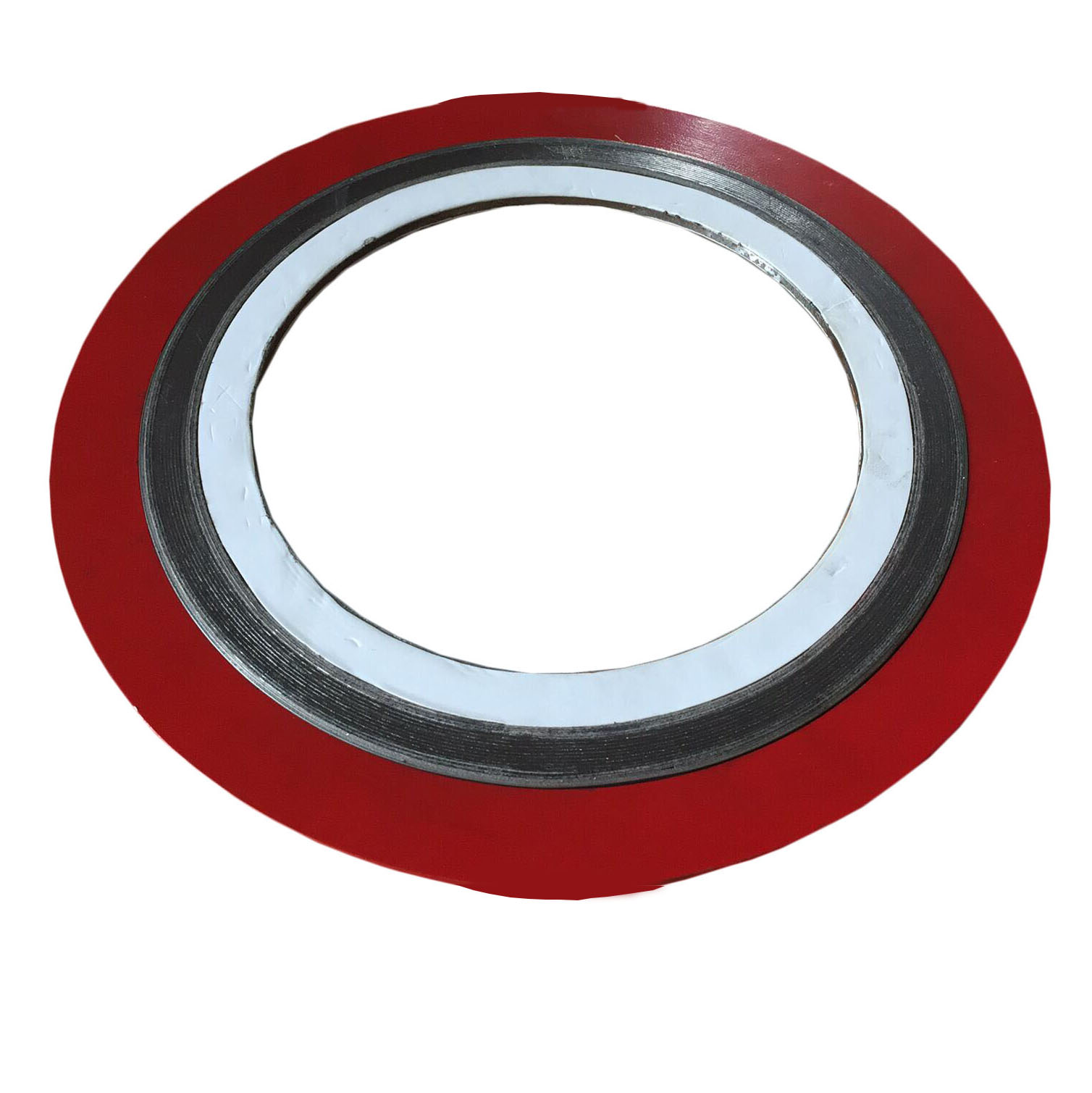

5. Yintoni i-spiral wound gasket?

I-spiral wound gasket yi-semi-metallic gasket equlathe iileya ezitshintshanayo zesinyithi kunye nezinto zokuzalisa (ngokuqhelekileyo i-graphite okanye i-PTFE). Ezi gasket zenzelwe ukubonelela ngesisombululo sokutywina esiqinileyo nesithembekileyo kwiintambo zeflange eziphantsi kobushushu obuphezulu, uxinzelelo kunye neendlela ezahlukeneyo zokusasaza.

6. Zisetyenziswa phi ii-spiral wound gaskets?

Iigaskets ze-Spiral wound zisetyenziswa kakhulu kumashishini afana nokucubungula iikhemikhali, ioyile negesi, iindawo zokucoca, ukuvelisa umbane kunye nemibhobho. Zifanelekile ukusetyenziswa ngomphunga, ii-hydrocarbons, ii-asidi kunye nezinye izinto ezibangela ukubola.

7. Ziziphi iingenelo zee-spiral wound gaskets?

Ezinye zeenzuzo zee-spiral wound gaskets ziquka ukumelana namaqondo obushushu aphezulu kunye noxinzelelo, ukuthamba okugqwesileyo, amandla okutywina agqwesileyo, ukuziqhelanisa nokungahambi kakuhle kweflange, kunye nokuhambelana okugqwesileyo kweekhemikhali. Ziyakwazi ukumelana nokuhamba kobushushu kunye nokugcina ukuthembeka kwetywina.

8. Ungayikhetha njani i-spiral wound gasket efanelekileyo?

Ukuze ukhethe i-spiral wound gasket efanelekileyo, cinga ngezinto ezifana nobushushu kunye noxinzelelo lokusebenza, uhlobo lolwelo, ukugqitywa komphezulu we-flange, ubungakanani be-flange, kunye nokuba khona kwayo nayiphi na imidiya ebolileyo. Ukubonisana nomthengisi we-gasket okanye umenzi kunokunceda ekuchongeni i-gasket efanelekileyo yokusetyenziswa.

9. Uyifaka njani i-spiral wound gasket?

Ukufaka i-spiral wound gasket, qiniseka ukuba ubuso be-flange bucocekile kwaye abunazo naziphi na iingceba okanye izinto ezindala ze-gasket. Beka i-washer kwi-flange uze ulungelelanise imingxunya ye-bolt. Faka uxinzelelo olulinganayo xa uqinisa ii-bolt ukuqinisekisa uxinzelelo olulinganayo kwi-gasket. Landela ulandelelwano olucetyiswayo lokuqinisa kunye namaxabiso e-torque anikezwe ngumvelisi we-gasket.

10. Ngaba ii-spiral wound gaskets zingasetyenziswa kwakhona?

Nangona ii-spiral wound gaskets zingasetyenziswa kwakhona kwezinye iimeko, kuyacetyiswa ukuba zitshintshwe ngee-gaskets ezintsha ukuqinisekisa ukusebenza kakuhle kokutywina. Ukusebenzisa ii-gaskets kwakhona kunokubangela ukuwohloka kokusebenza, ukulahleka kokucinezelwa, kunye nokuvuza okunokwenzeka. Kufuneka kulandelwe iindlela zokuhlola rhoqo kunye nokugcinwa kwazo ukuze kuchongwe ngokukhawuleza kwaye kutshintshwe ii-gaskets ezigugileyo.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.