INGCACISO

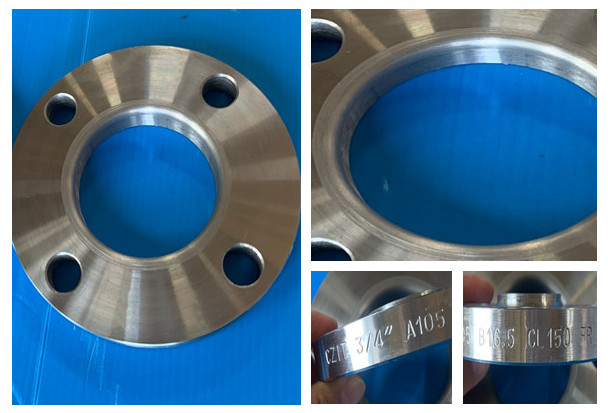

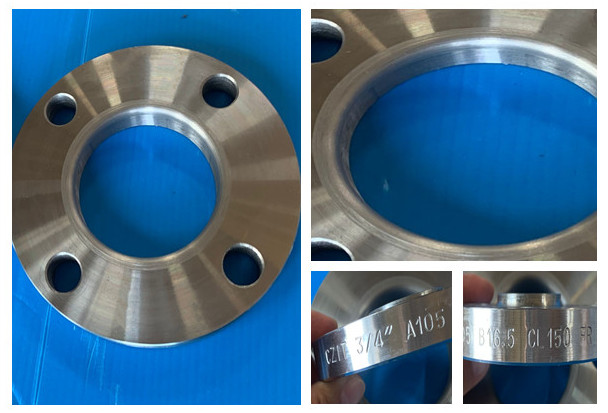

| Igama lemveliso | Umjikelo odityanisiweyo/Iflange ekhululekileyo |

| Ubungakanani | 1/2"-24" |

| Uxinzelelo | 150#-2500#,PN0.6-PN400,5K-40K |

| Umgangatho | ANSI B16.5,EN1092-1, JIS B2220 njl. |

| Isiphelo sestub | MSS SP 43, ASME B16.9 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 51,4147. 54Mo kunye njl. |

| Intsimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 njl. | |

| Duplex steel stainless:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 kunye njl. | |

| Intsimbi yombhobho:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | |

| I-nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 njl. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njl. | |

| Isicelo | Umzi-mveliso wepetrochemical;ishishini lenqwelomoya kunye ne-aerospace;ishishini loxubo-mayeza; umbhobho werhasi;iplanti yamandla;ukwakhiwa kweenqanawa;ukucocwa kwamanzi, njalo njalo. |

| Iingenelo | isitokhwe esilungile, ixesha lokuhambisa elikhawulezayo; lifumaneka kubo bonke ubungakanani, ngokwezifiso; umgangatho ophezulu |

IMIGANGATHO YOMLINGANISO

I-LAP JOINT FLANGE

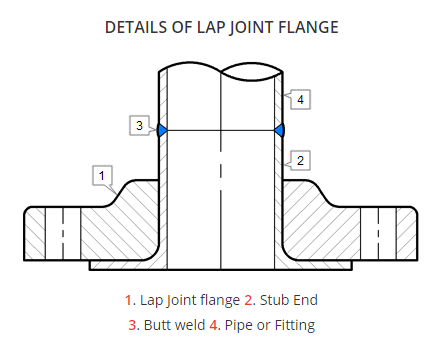

I-lap-joint flange ifuna amacandelo amabini emibhobho kwicala ngalinye loqhagamshelo olune-flanged, i-stub end kunye ne-backing flange ekhululekileyo.I-backing flange ekhululekileyo ilingana ngaphaya kwedayamitha yangaphandle yesiphelo se-stub, eboshwe nge-butt kumbhobho.I-backing flange ayidityaniswanga kumbhobho, kwaye inokujikelezwa, eyona nto ibaluleke kakhulu xa kuyimfuneko ukuqhelanisa ama-flanges ngexesha lokumisa.

Kwakhona, njengoko i-backing flange ingadibani nolwelo lwenkqubo, inokwenziwa ngento ekwaziyo ukumelana ne-corrosion.Ngokomzekelo, ukuba inkqubo i-corrosion kwaye idinga ukuba umbhobho ube yintsimbi engenasici, njengoko kwi-ASTM A312 TP316L, isiphelo se-stub kufuneka senziwe kwakhona nge-SS 316L;nangona kunjalo, i-backing flange inokwenziwa ngexabiso eliphantsi le-ASTM A105.

Le ndlela yokudibanisa ayinamandla njenge-weld neck flange kodwa iphezulu kune-screwed, i-socket weld, kunye ne-slip kwi-connections;nangona kunjalo, kubiza kakhulu ukuphumeza, kuba ifuna i-weld ye-butt yokungena ngokupheleleyo kwaye ifuna amacandelo amabini.

ISIPHELO SESIQINISO

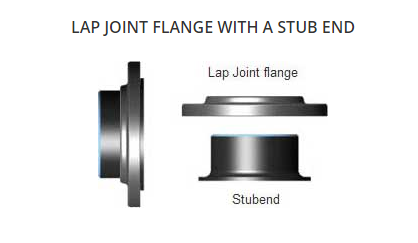

I-Stub End iya kuhlala isetyenziswa nge-Lap Joint flange, njengeflange exhasayo.

Oku kudityaniswa kwe-flange kuyasetyenziswa, kuxinzelelo oluphantsi kunye nezicelo ezingabalulekanga, kwaye yindlela enexabiso eliphantsi lokujika.

Kwinkqubo yepayipi yensimbi engenasici, umzekelo, i-carbon steel flange ingasetyenziswa, kuba ayidibanisi nemveliso kumbhobho.

Iziphelo zeStub ziyafumaneka phantse kuzo zonke iidamitha zemibhobho.Imilinganiselo kunye nokunyamezelwa kwe-dimensional kuchazwe kumgangatho we-ASME B.16.9.Iziphelo zeStub ezixhathisayo kubunzima bokukhanya (izifakelo) zichazwa kwi-MSS SP43.

I-ADVANTED YE-LAP JOINT FLANGE

- Inkululeko yokujikeleza kumbhobho iququzelela umgca wemingxuma yebholithi yeflange echasayo.

- Ukungabikho koqhagamshelwano nolwelo kumbhobho kudla ngokuvumela ukusetyenziswa kweeflange zensimbi zekhabhoni ezingabizi kunye nombhobho onganyangekiyo.

- Kwiinkqubo ezikhukulisekayo okanye ezitshatyalaliswayo ngokukhawuleza, iiflange zinokuhlangulwa ukuze ziphinde zisetyenziswe.

BONISA IINKCUKACHA zeeMveliso

1. Ubuso

ubuso flat, Radius yeyona ibalulekileyo

2. Nge hub okanye ngaphandle hub

3. Ukugqiba ubuso

Isiphelo kubuso beflange silinganiswa njenge-Arithmetical Average Roughness Height (AARH).Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo.Ngokomzekelo, i-ANSI B16.5 ichaza ukugqiba kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra).Ezinye ezigqityiweyo zifumaneka ngesicelo, umzekelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra.Uluhlu lwe-3.2 / 6.3Ra luqhelekileyo.

UKUMAKISHA NOKUPAKISHA

• Umaleko ngamnye sebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Ngokuba zonke intsimbi engatyiwa zipakishwe nge plywood case.Ubungakanani obukhulu bekhabhoni flange zipakishwe ngeplywood pallet.Okanye inokwenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lunokwenza ngesicelo

• Iimpawu kwiimveliso zinokukrolwa okanye ziprintwe.OEM yamkelwe.

UKUHLOLWA

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lweMT

• Uvavanyo lobungakanani

Ngaphambi kokunikezelwa, iqela lethu le-QC liya kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa komlinganiselo. Kwakhona yamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha Imathiriyeli ekrwada yokwenyani | 2. Sika imathiriyeli ekrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Ukutshiza ngokurhabaxa |

| 7. Ukugrumba | 8. Ukwenza kakuhle | 9. Ukumakisha |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukuhanjiswa |

I-lap-joint flange ifuna amacandelo amabini emibhobho kwicala ngalinye loqhagamshelo olune-flanged, i-stub end kunye ne-backing flange ekhululekileyo.I-backing flange ekhululekileyo ilingana ngaphaya kwedayamitha yangaphandle yesiphelo se-stub, eboshwe nge-butt kumbhobho.I-backing flange ayidityaniswanga kumbhobho, kwaye inokujikelezwa, eyona nto ibaluleke kakhulu xa kuyimfuneko ukuqhelanisa ama-flanges ngexesha lokumisa.

Kwakhona, njengoko i-backing flange ingadibani nolwelo lwenkqubo, inokwenziwa ngento ekwaziyo ukumelana ne-corrosion.Ngokomzekelo, ukuba inkqubo i-corrosion kwaye idinga ukuba umbhobho ube yintsimbi engenasici, njengoko kwi-ASTM A312 TP316L, isiphelo se-stub kufuneka senziwe kwakhona nge-SS 316L;nangona kunjalo, i-backing flange inokwenziwa ngexabiso eliphantsi le-ASTM A105.

Le ndlela yokudibanisa ayinamandla njenge-weld neck flange kodwa iphezulu kune-screwed, i-socket weld, kunye ne-slip kwi-connections;nangona kunjalo, kubiza kakhulu ukuphumeza, kuba ifuna i-weld ye-butt yokungena ngokupheleleyo kwaye ifuna amacandelo amabini.

I-Stub End iya kuhlala isetyenziswa nge-Lap Joint flange, njengeflange exhasayo.

Oku kudityaniswa kwe-flange kuyasetyenziswa, kuxinzelelo oluphantsi kunye nezicelo ezingabalulekanga, kwaye yindlela enexabiso eliphantsi lokujika.

Kwinkqubo yepayipi yensimbi engenasici, umzekelo, i-carbon steel flange ingasetyenziswa, kuba ayidibanisi nemveliso kumbhobho.

Iziphelo zeStub ziyafumaneka phantse kuzo zonke iidamitha zemibhobho.Imilinganiselo kunye nokunyamezelwa kwe-dimensional kuchazwe kumgangatho we-ASME B.16.9.Iziphelo zeStub ezixhathisayo kubunzima bokukhanya (izifakelo) zichazwa kwi-MSS SP43.

- Inkululeko yokujikeleza kumbhobho iququzelela umgca wemingxuma yebholithi yeflange echasayo.

- Ukungabikho koqhagamshelwano nolwelo kumbhobho kudla ngokuvumela ukusetyenziswa kweeflange zensimbi zekhabhoni ezingabizi kunye nombhobho onganyangekiyo.

- Kwiinkqubo ezikhukulisekayo okanye ezitshatyalaliswayo ngokukhawuleza, iiflange zinokuhlangulwa ukuze ziphinde zisetyenziswe.

Iimveliso zibonisa iinkcukacha

1. Ubuso

ubuso flat, Radius yeyona ibalulekileyo

2. Nge hub okanye ngaphandle hub

3. Ukugqiba ubuso

Isiphelo kubuso beflange silinganiswa njenge-Arithmetical Average Roughness Height (AARH).Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo.Ngokomzekelo, i-ANSI B16.5 ichaza ukugqiba kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra).Ezinye ezigqityiweyo zifumaneka ngesicelo, umzekelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra.Uluhlu lwe-3.2 / 6.3Ra luqhelekileyo.

Ukumakisha nokupakisha

• Umaleko ngamnye sebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Ngokuba zonke intsimbi engatyiwa zipakishwe nge plywood case.Ubungakanani obukhulu bekhabhoni flange zipakishwe ngeplywood pallet.Okanye inokwenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lunokwenza ngesicelo

• Iimpawu kwiimveliso zinokukrolwa okanye ziprintwe.OEM yamkelwe.

Ukuhlolwa

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lweMT

• Uvavanyo lobungakanani

Ngaphambi kokunikezelwa, iqela lethu le-QC liya kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa komlinganiselo. Kwakhona yamkela i-TPI (ukuhlolwa komntu wesithathu).

Inkqubo yokuvelisa

| 1. Khetha Imathiriyeli ekrwada yokwenyani | 2. Sika imathiriyeli ekrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Ukutshiza ngokurhabaxa |

| 7. Ukugrumba | 8. Ukwenza kakuhle | 9. Ukumakisha |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukuhanjiswa |

-

orifice flange WN 4″ 900# RF A105 ezimbini gr...

-

ASME B16.5 BL RF ASTM A182 F316L Stainless stee...

-

Socket weld flange A105 carbon steel SW RTJ 3/4...

-

AMSE B16.5 A105 forged carbon steel weld intamo f...

-

Insimbi engenaStainless 304 304L 316 316L ASTM yenziwe ...

-

carbon steel weld intamo uhlobo 6 ″ ANSI CLASS...