IINKCUKACHA

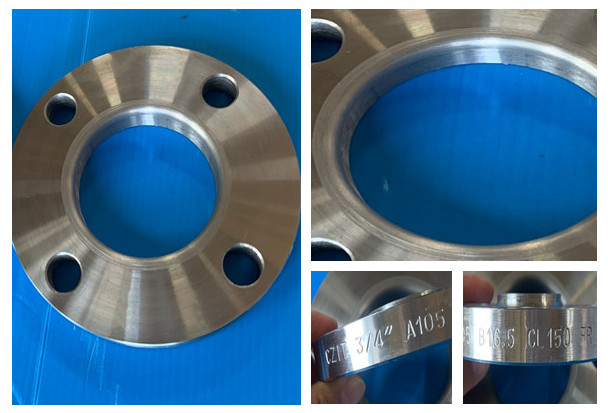

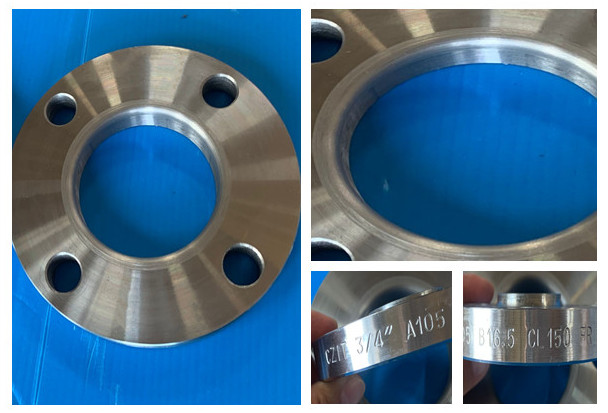

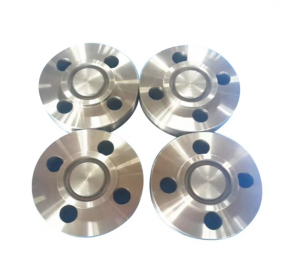

| Igama lemveliso | I-Lap joint/I-flange ekhululekileyo |

| Ubungakanani | 1/2"-24" |

| Uxinzelelo | 150#-2500#,PN0.6-PN400,5K-40K |

| Umgangatho | ANSI B16.5,EN1092-1, JIS B2220 njl. |

| Isiphelo sestub | I-MSS SP 43, i-ASME B16.9 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njl. |

| Intsimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njl. | |

| Intsimbi engagqwaliyo ephindwe kabini:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njl. | |

| Intsimbi yombhobho:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | |

| I-alloy ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 njl. | |

| I-Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza; umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

IMIGANGATHO YODWALA

I-FLANGE EJONGENEYO YESIQHINGA

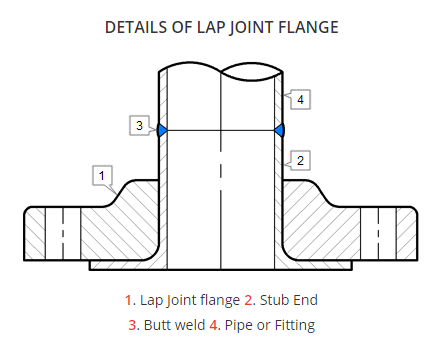

I-flange edibeneyo ifuna izinto ezimbini zombhobho kwicala ngalinye loqhagamshelo oludibeneyo, isiphelo se-stub kunye ne-backing flange ekhululekileyo. I-backing flange ekhululekileyo ingena phezu kobubanzi bangaphandle besiphelo se-stub, esidityaniswe nge-butt-welded kumbhobho. I-backing flange ayidityaniswe kumbhobho, kwaye ingajikeleziswa, nto leyo eluncedo kakhulu xa kufuneka uqondise ii-flanges ngexesha lokumiswa.

Kwakhona, njengoko i-backing flange ingadibani nolwelo lwenkqubo, inokwenziwa ngezinto ezingamelani nokubola kakhulu. Umzekelo, ukuba inkqubo iyabola kwaye ifuna ukuba umbhobho ube yintsimbi engagqwaliyo, njengakwi-ASTM A312 TP316L, isiphelo se-stub kufuneka senziwe nge-SS 316L; nangona kunjalo, i-backing flange ingenziwa nge-ASTM A105 engabizi kakhulu.

Le ndlela yokudibanisa ayinamandla njenge-weld neck flange kodwa ingcono kune-screwed, socket weld, kunye ne-slip on connections; nangona kunjalo, ibiza kakhulu ukuyenza, kuba ifuna i-full-penetration butt weld kwaye ifuna izinto ezimbini.

ISIPHELO SESITYA

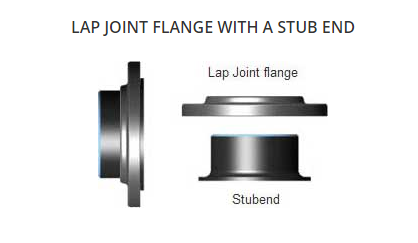

Isiphelo seStub siya kuhlala sisetyenziswa kunye neflange yeLap Joint, njengeflange engasemva.

Olu qhagamshelo lweflange lusetyenziswa, kwiindawo ezinoxinzelelo oluphantsi kunye nezicelo ezingabalulekanga, kwaye yindlela engabizi kakhulu yokuflange.

Kwinkqubo yemibhobho yentsimbi engagqwaliyo, umzekelo, i-flange yentsimbi yekhabhoni ingafakwa, kuba ayidibani nemveliso ekwimibhobho.

IiStub Ends zifumaneka phantse kuzo zonke iidayamitha zepayipi. Ubukhulu kunye nokunyamezelana kobukhulu buchazwe kumgangatho we-ASME B.16.9. IiStub Ends (izixhobo) ezingamelaniyo nokugqwala zichazwe kwi-MSS SP43.

Iluncedo kwi-Lap Joint Flange

- Inkululeko yokujikajika ijikeleze umbhobho yenza kube lula ukujikeleza imingxunya yebholthi yeflange echaseneyo.

- Ukungabikho koqhagamshelwano nolwelo olukwipayipi kudla ngokuvumela ukusetyenziswa kwee-flanges zentsimbi yekhabhoni ezingabizi kakhulu ezinepayipi ekwaziyo ukumelana nokugqwala.

- Kwiinkqubo ezibola okanye ezibola ngokukhawuleza, iiflanges zinokugcinwa ukuze zisetyenziswe kwakhona.

IINKCUKACHA ZEMVELISO UMBONO

1. Ubuso

ubuso obuthe tyaba, iRadius yeyona ibalulekileyo

2. Ngehabhu okanye ngaphandle kwehabhu

3. Ukugqiba ubuso

Ukugqitywa kobuso beflange kulinganiswa njengoBude obuPhakathi boBuqatha be-Arithmetical (AARH). Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo. Umzekelo, i-ANSI B16.5 ichaza ukugqitywa kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra). Ezinye ukugqitywa ziyafumaneka xa kufunwa, umzekelo i-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra. Uluhlu lwe-3.2/6.3Ra lolona luxhaphakileyo.

UKUPHAKISHA NOKUPAKISHA

• Umaleko ngamnye usebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Kuzo zonke intsimbi engagqwaliyo zipakishwa ngebhokisi yeplywood. Ukuze zibe neflange enkulu yekhabhoni zipakishwa ngepallet yeplywood. Okanye zingenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lungenziwa xa luceliwe

• Iimpawu kwiimveliso zingabanjiswa okanye ziprintwe. I-OEM iyamkelwa.

UVAVANYO

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lwe-MT

• Uvavanyo lobukhulu

Ngaphambi kokuba ifike, iqela lethu le-QC liza kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa kobukhulu. Kwakhona lamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha izinto zokwenyani | 2. Sika izinto ezikrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Umatshini Onzima |

| 7. Ukubhola | 8. Ukuluka kakuhle | 9. Ukumakisha |

| 10. Uhlolo | 11. Ukupakisha | 12. Ukuhanjiswa |

I-flange edibeneyo ifuna izinto ezimbini zombhobho kwicala ngalinye loqhagamshelo oludibeneyo, isiphelo se-stub kunye ne-backing flange ekhululekileyo. I-backing flange ekhululekileyo ingena phezu kobubanzi bangaphandle besiphelo se-stub, esidityaniswe nge-butt-welded kumbhobho. I-backing flange ayidityaniswe kumbhobho, kwaye ingajikeleziswa, nto leyo eluncedo kakhulu xa kufuneka uqondise ii-flanges ngexesha lokumiswa.

Kwakhona, njengoko i-backing flange ingadibani nolwelo lwenkqubo, inokwenziwa ngezinto ezingamelani nokubola kakhulu. Umzekelo, ukuba inkqubo iyabola kwaye ifuna ukuba umbhobho ube yintsimbi engagqwaliyo, njengakwi-ASTM A312 TP316L, isiphelo se-stub kufuneka senziwe nge-SS 316L; nangona kunjalo, i-backing flange ingenziwa nge-ASTM A105 engabizi kakhulu.

Le ndlela yokudibanisa ayinamandla njenge-weld neck flange kodwa ingcono kune-screwed, socket weld, kunye ne-slip on connections; nangona kunjalo, ibiza kakhulu ukuyenza, kuba ifuna i-full-penetration butt weld kwaye ifuna izinto ezimbini.

Isiphelo seStub siya kuhlala sisetyenziswa kunye neflange yeLap Joint, njengeflange engasemva.

Olu qhagamshelo lweflange lusetyenziswa, kwiindawo ezinoxinzelelo oluphantsi kunye nezicelo ezingabalulekanga, kwaye yindlela engabizi kakhulu yokuflange.

Kwinkqubo yemibhobho yentsimbi engagqwaliyo, umzekelo, i-flange yentsimbi yekhabhoni ingafakwa, kuba ayidibani nemveliso ekwimibhobho.

IiStub Ends zifumaneka phantse kuzo zonke iidayamitha zepayipi. Ubukhulu kunye nokunyamezelana kobukhulu buchazwe kumgangatho we-ASME B.16.9. IiStub Ends (izixhobo) ezingamelaniyo nokugqwala zichazwe kwi-MSS SP43.

- Inkululeko yokujikajika ijikeleze umbhobho yenza kube lula ukujikeleza imingxunya yebholthi yeflange echaseneyo.

- Ukungabikho koqhagamshelwano nolwelo olukwipayipi kudla ngokuvumela ukusetyenziswa kwee-flanges zentsimbi yekhabhoni ezingabizi kakhulu ezinepayipi ekwaziyo ukumelana nokugqwala.

- Kwiinkqubo ezibola okanye ezibola ngokukhawuleza, iiflanges zinokugcinwa ukuze zisetyenziswe kwakhona.

Iinkcukacha zemveliso zibonisa

1. Ubuso

ubuso obuthe tyaba, iRadius yeyona ibalulekileyo

2. Ngehabhu okanye ngaphandle kwehabhu

3. Ukugqiba ubuso

Ukugqitywa kobuso beflange kulinganiswa njengoBude obuPhakathi boBuqatha be-Arithmetical (AARH). Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo. Umzekelo, i-ANSI B16.5 ichaza ukugqitywa kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra). Ezinye ukugqitywa ziyafumaneka xa kufunwa, umzekelo i-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra. Uluhlu lwe-3.2/6.3Ra lolona luxhaphakileyo.

Ukumakisha kunye nokupakisha

• Umaleko ngamnye usebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Kuzo zonke intsimbi engagqwaliyo zipakishwa ngebhokisi yeplywood. Ukuze zibe neflange enkulu yekhabhoni zipakishwa ngepallet yeplywood. Okanye zingenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lungenziwa xa luceliwe

• Iimpawu kwiimveliso zingabanjiswa okanye ziprintwe. I-OEM iyamkelwa.

Uhlolo

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lwe-MT

• Uvavanyo lobukhulu

Ngaphambi kokuba ifike, iqela lethu le-QC liza kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa kobukhulu. Kwakhona lamkela i-TPI (ukuhlolwa komntu wesithathu).

Inkqubo yemveliso

| 1. Khetha izinto zokwenyani | 2. Sika izinto ezikrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Umatshini Onzima |

| 7. Ukubhola | 8. Ukuluka kakuhle | 9. Ukumakisha |

| 10. Uhlolo | 11. Ukupakisha | 12. Ukuhanjiswa |

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

Izixhobo zePipe A105 Class 150 Ss Carbon Steel Pl ...

-

I-welding yentsimbi ephakanyisiweyo ubuso beflegi EN1092-1 uhlobo0 ...

-

I-304 Stainless Steel Flanged Custom High Quality ...

-

i-flange ye-asme b16.36 wn eyenziwe nge-orifice ene-Jack ...

-

I-ASME B16.5 BL RF ASTM A182 F316L Intsimbi engenasici ...

-

I-ASTM A182 F51 F53 BL ANSI B16.5 Intsimbi engenasici...