INGCACISO

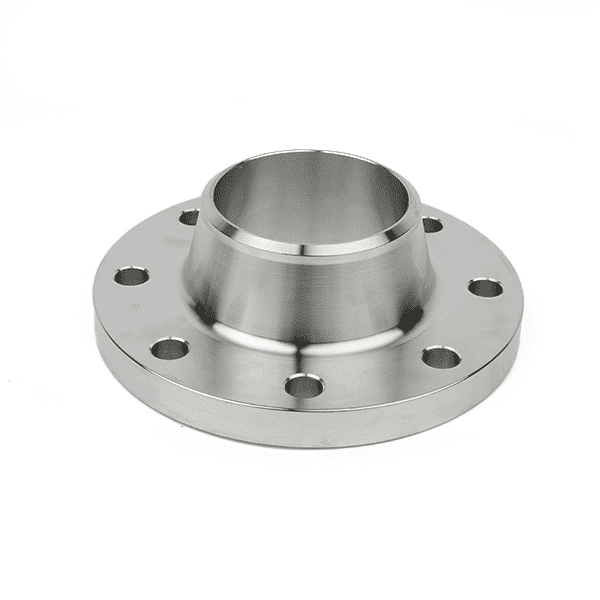

| Igama lemveliso | Umjikelo odityanisiweyo/Iflange ekhululekileyo |

| Ubungakanani | 1/2"-24" |

| Uxinzelelo | 150#-2500#,PN0.6-PN400,5K-40K |

| Umgangatho | ANSI B16.5,EN1092-1, JIS B2220 njl. |

| Isiphelo sestub | MSS SP 43, ASME B16.9 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 51,4147. 54Mo kunye njl. |

| Intsimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 njl. | |

| Duplex steel stainless:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 kunye njl. | |

| Intsimbi yombhobho:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | |

| I-nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 njl. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njl. | |

| Isicelo | Umzi-mveliso wepetrochemical;ishishini lenqwelomoya kunye ne-aerospace;ishishini loxubo-mayeza; umbhobho werhasi;iplanti yamandla;ukwakhiwa kweenqanawa;ukucocwa kwamanzi, njalo njalo. |

| Iingenelo | isitokhwe esilungile, ixesha lokuhambisa elikhawulezayo; lifumaneka kubo bonke ubungakanani, ngokwezifiso; umgangatho ophezulu |

IMIGANGATHO YOMLINGANISO

BONISA IINKCUKACHA zeeMveliso

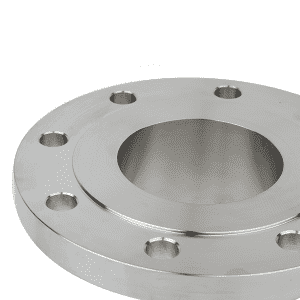

1. Ubuso

Inokunyuswa ubuso (RF), ubuso obugcweleyo (FF), iRing joint(RTJ) , Groove, Language, okanye ngokwezifiso.

2.Bevel ekupheleni ngokwe ANSI B16.25

Isohlwayo se-3.CNC sigqityiwe.

Ukugqitywa kobuso: Ukugqitywa kobuso beflange kulinganiswa njenge-Arithmetical Average Roughness Height (AARH).Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo.Ngokomzekelo, i-ANSI B16.5 ichaza ukugqiba kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra).Ezinye ezigqityiweyo zifumaneka ngesicelo, umzekelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra.Uluhlu lwe-3.2 / 6.3Ra luqhelekileyo.

UKUMAKISHA NOKUPAKISHA

• Umaleko ngamnye sebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Ngokuba zonke intsimbi engatyiwa zipakishwe nge plywood case.Ubungakanani obukhulu bekhabhoni flange zipakishwe ngeplywood pallet.Okanye inokwenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lunokwenza ngesicelo

• Iimpawu kwiimveliso zinokukrolwa okanye ziprintwe.OEM yamkelwe.

UKUHLOLWA

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lweMT

• Uvavanyo lobungakanani

Ngaphambi kokunikezelwa, iqela lethu le-QC liya kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa komlinganiselo. Kwakhona yamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha Imathiriyeli ekrwada yokwenyani | 2. Sika imathiriyeli ekrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Ukutshiza ngokurhabaxa |

| 7. Ukugrumba | 8. Ukwenza kakuhle | 9. Ukumakisha |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukuhanjiswa |

ICALA LENTSEBENZISWANO

Iprojekthi eTurkey, iiflange zisetyenziselwa imibhobho yegesi yendalo.Zonke ezo flange zivunyiwe yiTUV.

FLANGE IPHEPHA LEDATHA

1.Imilinganiselo yeflange kunye nokunyamezela kuya kuba ngokwe ASME B16.5.

2. Iiflange ziya kuveliswa ngokubumba.

3. Izinto eziphathekayo ziya kuba ngokwemigangatho ye-ASTM A105, ASTM A694 F65 kunye ne-ASTM A694 F70.

4. I-ASTM A694 F65 kunye ne-ASTM A694 F70 flanges ziya kucinywa kwaye zihlanjululwe.

5. Izatifikethi zovavanyo lwezinto eziphathekayo kunye neengxelo zokunyanga ubushushu ziya kwenziwa zifumaneke kuhlolo lwe-TPI.

6. Iiflange zeWN ziya kuba nebevel ends acc.ukuya ASME B16.25.

7. Amaxabiso eekhemikhali neekhemikhali zovavanyo lwezixhobo (impembelelo, isivuno, ukuqina njalo njalo) aya kuhambelana nemigangatho enxulumeneyo.

8. Yonke imiphezulu iya kwenziwa ngoomatshini kwaye ivanishwe nge-oyile ecacileyo ukuthintela ukurusa.

9. Ukumakisha kuya kubandakanya olu lwazi lulandelayo,

• Ububanzi (exp. 6”)

• Udidi loxinzelelo (exp. 150 LB)

• IBanga leMathiriyeli (exp. ASTM A 105)

• Ubukhulu bodonga (exp. 4,78 mm)

• Inombolo yobushushu (exp. 138413)

• Umgangatho wemveliso (ASME B16.5)

10. Izinto eziphathekayo aziyi kukhululeka kuzo naziphi na iziphene kunye neentanda.Ukulungiswa kwe-welding akuvumelekanga ngokungqongqo.

11. Zonke iiflange ziya kuphakanyiswa ubuso (RF) kunye nomphezulu wokutywina.Umphezulu wokutywina uya kuba yiRa 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.ukuya ASME B46.1.

12. Izinto eziphathekayo ziya kupakishwa ukukhusela umonakalo kumatshini, kunye nokutywinwa kwendawo.

13. Yonke imilinganiso iya kuba kwi-positive (+) yokunyamezelana.Ukunyamezelwa kweMinus akuvumelekanga ngokungqongqo.

14. Iibevelings zeflange ziya kwenziwa ukuba zihambelane.ukuya ASME B16.25.

15. Inkqubo yokwenziwa kwezinto iya kujongwa nangaliphi na ixesha yi-TPI.

16. I-TPI inokuthatha iisampulu kuyo nayiphi na imathiriyeli yesampulu yovavanyo lwekhemikhali/yomatshini.

17. Ingxelo yohlolo olungenayo iya kuhlolwa yiTPI.

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | IIFLANGE ZETANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 16 |

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Ziziphi iintlobo ezahlukeneyo zemibhobho yensimbi engenasici?

Impendulo: Izixhobo zombhobho zensimbi ezingenasici zibandakanya ukufakwa kombhobho we-butt welding, i-socket welding pipe fittings, i-threaded pipe fittings, i-flanges, i-valve kunye nezinye iintlobo.

2. Uthini umahluko phakathi kwensimbi engenasici kwi-304 kunye ne-316 yokufakelwa kwepayipi yensimbi engenasici?

A: I-304 yensimbi engenasici ifanelekile kwizicelo ezininzi kwaye inokumelana ne-corrosion.I-316 insimbi engagqwali, kwelinye icala, inokumelana ne-corrosion engcono kwindawo ezonakalisa kakhulu kwaye ifanelekele ukusetyenziswa kolwandle kunye neekhemikhali.

3. Zeziphi iingenelo zokusebenzisa imibhobho edityanisiweyo ngempundu?

IMPENDULO: Ufakelo lwe-weld lwe-butt olwandisiweyo lunika ukomelela, ukuthembeka, kunye noqhagamshelwano olungavuziyo.Banikezela ukuchasana kwempembelelo egqwesileyo kwaye bakhethwa kuxinzelelo oluphezulu kunye nezicelo zobushushu obuphezulu.

4. Yintoni i-butt welding flange?

Impendulo: I-butt ye-welding flange yi-flange yombhobho ene-hub ende ene-tapered kwaye idityaniswe kumbhobho.Inika inguqu egudileyo ukusuka kumbhobho ukuya kwiflange ngamandla amakhulu kunye nokuthembeka.

5. Yiyiphi ibakala yensimbi engenasici esetyenziswa ngokuqhelekileyo kwimibhobho yokufakelwa?

A: I-Stainless steel grade 304, 316, 304L, 316L kunye ne-317 zisetyenziswa ngokuqhelekileyo kwizixhobo zombhobho ngenxa yokumelana nokugqwesa, ukuqina kunye nokuguquguquka.

6. Ngaba izixhobo zemibhobho yensimbi engenasici zinokusetyenziswa kwizicelo zokushisa okuphezulu?

Impendulo: Ewe, izixhobo zensimbi ezingenasici zifanelekile kwizicelo zokushisa okuphezulu.Nangona kunjalo, ibakala lensimbi engenasici esetyenzisiweyo kufuneka likhethwe ngokucophelela ngokusekelwe kwiimfuno ezithile zokushisa kwesicelo.

7. Ngaba izixhobo zombhobho zensimbi ezingenasici zifanelekile kwishishini lokutya kunye nesiselo?

Impendulo: Ewe, izixhobo zepayipi zensimbi ezingenasici zisetyenziswa ngokubanzi kwishishini lokutya kunye nesiselo ngenxa yokucoceka kwazo, ukuxhathisa ukubola, kunye nokugcinwa lula.

8. Uthini umahluko phakathi kokufakwa kwe-welding ye-socket kunye ne-butt welding fittings?

Impendulo: Izixhobo zombhobho we-socket welding faka umbhobho kwi-socket uze wenze i-fillet welding ukudibanisa umbhobho.I-butt weld fittings, kwelinye icala, ifuna ukuba iziphelo zombhobho zibhijelwe kwaye zidibanise.

9. Ngaba izifakelo zemibhobho yentsimbi engatyiwayo zinokuphinda zisetyenziswe?

A: Ewe, izifakelo zemibhobho yentsimbi etyiwayo zinokuphinda zisetyenziswe.Insimbi engenasici yinto ezinzileyo enokuthi ihlaziywe kwaye isetyenziswe kwakhona ngaphandle kokulahlekelwa iimpawu zayo okanye umgangatho.

10. Ziziphi iingenelo zokusebenzisa izixhobo zemibhobho yensimbi engenasici xa kuthelekiswa nezinye izinto?

A: Izixhobo zombhobho zensimbi ezingenasici zibonelela ngeenzuzo ezininzi, ezifana nokumelana nokugqwesa okugqwesileyo, amandla aphezulu, ukuqina kunye neempawu ezicocekileyo.Zinokugcinwa okuphantsi, zinobomi obude kwaye zinembonakalo ecocekileyo nenhle.

BONISA IINKCUKACHA zeeMveliso

1. Ubuso

Inokunyuswa ubuso (RF), ubuso obugcweleyo (FF), iRing joint(RTJ) , Groove, Language, okanye ngokwezifiso.

2.Bevel ekupheleni ngokwe ANSI B16.25

Isohlwayo se-3.CNC sigqityiwe.

Ukugqitywa kobuso: Ukugqitywa kobuso beflange kulinganiswa njenge-Arithmetical Average Roughness Height (AARH).Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo.Ngokomzekelo, i-ANSI B16.5 ichaza ukugqiba kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra).Ezinye ezigqityiweyo zifumaneka ngesicelo, umzekelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra.Uluhlu lwe-3.2 / 6.3Ra luqhelekileyo.

UKUMAKISHA NOKUPAKISHA

• Umaleko ngamnye sebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Ngokuba zonke intsimbi engatyiwa zipakishwe nge plywood case.Ubungakanani obukhulu bekhabhoni flange zipakishwe ngeplywood pallet.Okanye inokwenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lunokwenza ngesicelo

• Iimpawu kwiimveliso zinokukrolwa okanye ziprintwe.OEM yamkelwe.

UKUHLOLWA

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lweMT

• Uvavanyo lobungakanani

Ngaphambi kokunikezelwa, iqela lethu le-QC liya kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa komlinganiselo. Kwakhona yamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha Imathiriyeli ekrwada yokwenyani | 2. Sika imathiriyeli ekrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Ukutshiza ngokurhabaxa |

| 7. Ukugrumba | 8. Ukwenza kakuhle | 9. Ukumakisha |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukuhanjiswa |

ICALA LENTSEBENZISWANO

Iprojekthi eTurkey, iiflange zisetyenziselwa imibhobho yegesi yendalo.Zonke ezo flange zivunyiwe yiTUV.

FLANGE IPHEPHA LEDATHA

1. Imilinganiselo ye-Flange kunye nokunyamezela kuya kuba ngokwe-ASME B16.5.

2. Iiflange ziya kuveliswa ngokubumba.

3. Izinto eziphathekayo ziya kuba ngokwemigangatho ye-ASTM A105, ASTM A694 F65 kunye ne-ASTM A694 F70.

4. I-ASTM A694 F65 kunye ne-ASTM A694 F70 flanges ziya kucinywa kwaye zihlanjululwe.

5. Izatifikethi zovavanyo lwezinto eziphathekayo kunye neengxelo zokunyanga ubushushu ziya kwenziwa zifumaneke kuhlolo lwe-TPI.

6. Iiflange zeWN ziya kuba nebevel ends acc.ukuya ASME B16.25.

7. Amaxabiso eekhemikhali neekhemikhali zovavanyo lwezixhobo (impembelelo, isivuno, ukuqina njalo njalo) aya kuhambelana nemigangatho enxulumeneyo.

8. Yonke imiphezulu iya kwenziwa ngoomatshini kwaye ivanishwe nge-oyile ecacileyo ukuthintela ukurusa.

9. Ukumakisha kuya kubandakanya olu lwazi lulandelayo,

• Ububanzi (exp. 6”)

• Udidi loxinzelelo (exp. 150 LB)

• IBanga leMathiriyeli (exp. ASTM A 105)

• Ubukhulu bodonga (exp. 4,78 mm)

• Inombolo yobushushu (exp. 138413)

• Umgangatho wemveliso (ASME B16.5)

10. Izinto eziphathekayo aziyi kukhululeka kuzo naziphi na iziphene kunye neentanda.Ukulungiswa kwe-welding akuvumelekanga ngokungqongqo.

11. Zonke iiflange ziya kuphakanyiswa ubuso (RF) kunye nomphezulu wokutywina.Umphezulu wokutywina uya kuba yiRa 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.ukuya ASME B46.1.

12. Izinto eziphathekayo ziya kupakishwa ukukhusela umonakalo kumatshini, kunye nokutywinwa kwendawo.

13. Yonke imilinganiso iya kuba kwi-positive (+) yokunyamezelana.Ukunyamezelwa kweMinus akuvumelekanga ngokungqongqo.

14. Iibevelings zeflange ziya kwenziwa ukuba zihambelane.ukuya ASME B16.25.

15. Inkqubo yokwenziwa kwezinto iya kujongwa nangaliphi na ixesha yi-TPI.

16. I-TPI inokuthatha iisampulu kuyo nayiphi na imathiriyeli yesampulu yovavanyo lwekhemikhali/yomatshini.

17. Ingxelo yohlolo olungenayo iya kuhlolwa yiTPI.

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | IIFLANGE ZETANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 16 |

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

-

Steel welding waphakamisa ubuso flange EN1092-1 type0...

-

WN ANSI B16.36 orifice weld intamo flange nge ja...

-

Socket weld flange A105 carbon steel SW RTJ 3/4...

-

Screw BSP DIN PN 10/16 carbon steel A105 flange...

-

bheqa isithuba esingenanto A515 gr 60 umfanekiso 8 umbono...

-

ASME B16.48 CL150 CL300 Isiphekepheke seplanga yeplanga...