INGCACISO

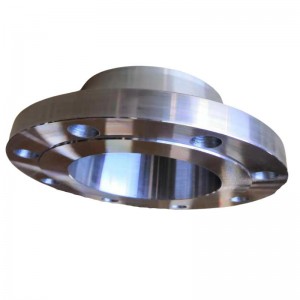

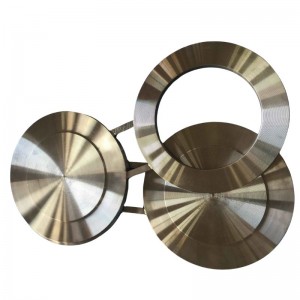

| Igama lemveliso | weld intamo flange |

| Ubungakanani | 1/2"-24" |

| Uxinzelelo | 150#-2500#,PN0.6-PN400,5K-40K |

| Umgangatho | ANSI B16.5,EN1092-1, JIS B2220 njl. |

| Isiphelo sestub | MSS SP 43, ASME B16.9 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 51,4147. 54Mo kunye njl. |

| Intsimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 njl. | |

| Duplex steel stainless:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 kunye njl. | |

| Intsimbi yombhobho:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | |

| I-nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 njl. | |

| Ingxubevange ye-Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njl. | |

| Isicelo | Umzi-mveliso wepetrochemical;ishishini lenqwelomoya kunye ne-aerospace;ishishini loxubo-mayeza; umbhobho werhasi;iplanti yamandla;ukwakhiwa kweenqanawa;ukucocwa kwamanzi, njalo njalo. |

| Iingenelo | isitokhwe esilungile, ixesha lokuhambisa elikhawulezayo; lifumaneka kubo bonke ubungakanani, ngokwezifiso; umgangatho ophezulu |

IMIGANGATHO YOMLINGANISO

BONISA IINKCUKACHA zeeMveliso

1. Ubuso

Inokunyuswa ubuso (RF), ubuso obugcweleyo (FF), iRing joint(RTJ) , Groove, Language, okanye ngokwezifiso.

2.Bevel ekupheleni ngokwe ANSI B16.25

Isohlwayo se-3.CNC sigqityiwe.

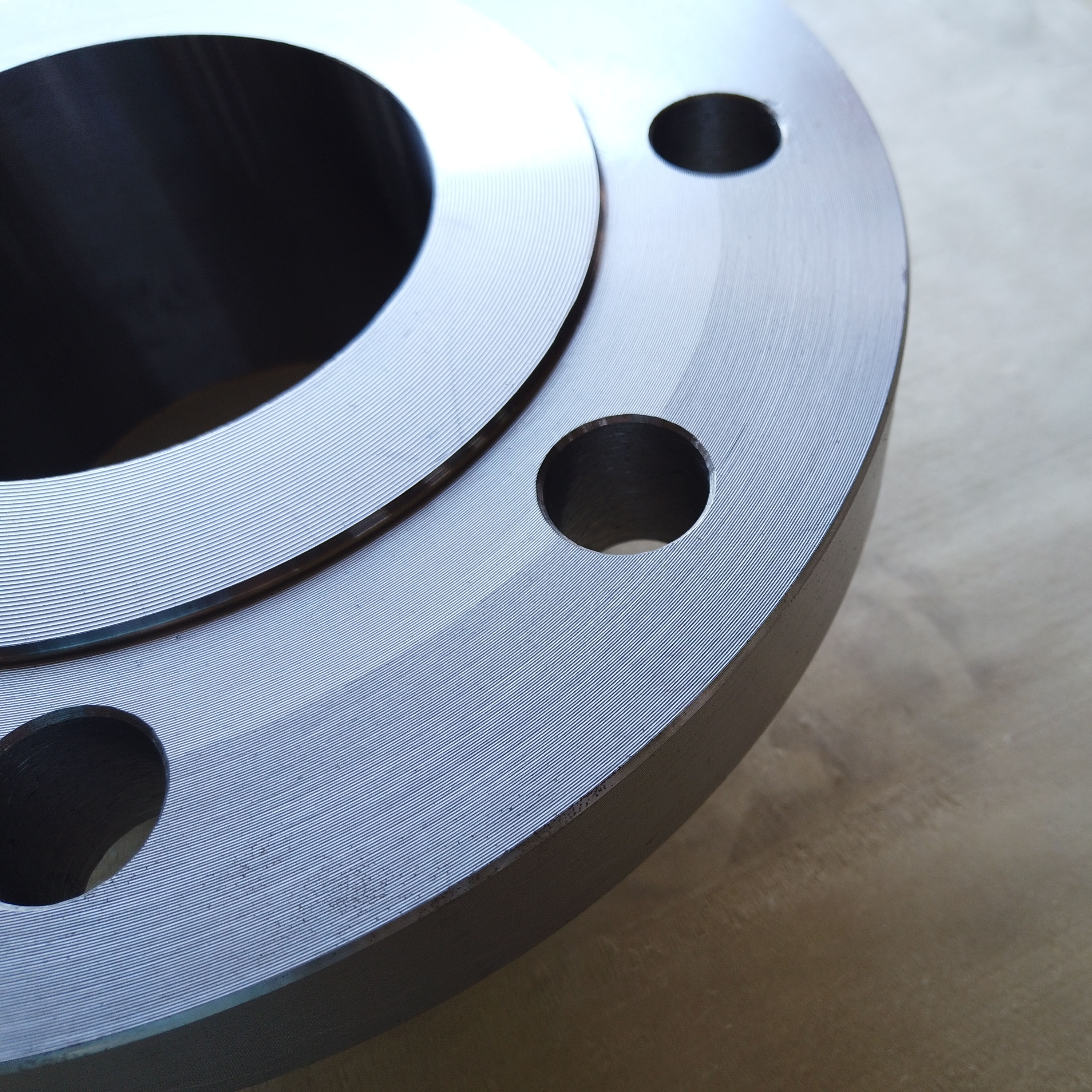

Ukugqitywa kobuso: Ukugqitywa kobuso beflange kulinganiswa njenge-Arithmetical Average Roughness Height (AARH).Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo.Ngokomzekelo, i-ANSI B16.5 ichaza ukugqiba kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra).Ezinye ezigqityiweyo zifumaneka ngesicelo, umzekelo 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra.Uluhlu lwe-3.2 / 6.3Ra luqhelekileyo.

UKUMAKISHA NOKUPAKISHA

• Umaleko ngamnye sebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Ngokuba zonke intsimbi engatyiwa zipakishwe nge plywood case.Ubungakanani obukhulu bekhabhoni flange zipakishwe ngeplywood pallet.Okanye inokwenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lunokwenza ngesicelo

• Iimpawu kwiimveliso zinokukrolwa okanye ziprintwe.OEM yamkelwe.

UKUHLOLWA

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lweMT

• Uvavanyo lobungakanani

Ngaphambi kokunikezelwa, iqela lethu le-QC liya kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa komlinganiselo. Kwakhona yamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha Imathiriyeli ekrwada yokwenyani | 2. Sika imathiriyeli ekrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Ukutshiza ngokurhabaxa |

| 7. Ukugrumba | 8. Ukwenza kakuhle | 9. Ukumakisha |

| 10. Ukuhlolwa | 11. Ukupakisha | 12. Ukuhanjiswa |

ICALA LENTSEBENZISWANO

Iprojekthi eTurkey, iiflange zisetyenziselwa imibhobho yegesi yendalo.Zonke ezo flange zivunyiwe yiTUV.

FLANGE IPHEPHA LEDATHA

1.Imilinganiselo yeflange kunye nokunyamezela kuya kuba ngokwe ASME B16.5.

2. Iiflange ziya kuveliswa ngokubumba.

3. Izinto eziphathekayo ziya kuba ngokwemigangatho ye-ASTM A105, ASTM A694 F65 kunye ne-ASTM A694 F70.

4. I-ASTM A694 F65 kunye ne-ASTM A694 F70 flanges ziya kucinywa kwaye zihlanjululwe.

5. Izatifikethi zovavanyo lwezinto eziphathekayo kunye neengxelo zokunyanga ubushushu ziya kwenziwa zifumaneke kuhlolo lwe-TPI.

6. Iiflange zeWN ziya kuba nebevel ends acc.ukuya ASME B16.25.

7. Amaxabiso eekhemikhali neekhemikhali zovavanyo lwezixhobo (impembelelo, isivuno, ukuqina njalo njalo) aya kuhambelana nemigangatho enxulumeneyo.

8. Yonke imiphezulu iya kwenziwa ngoomatshini kwaye ivanishwe nge-oyile ecacileyo ukuthintela ukurusa.

9. Ukumakisha kuya kubandakanya olu lwazi lulandelayo,

• Ububanzi (exp. 6”)

• Udidi loxinzelelo (exp. 150 LB)

• IBanga leMathiriyeli (exp. ASTM A 105)

• Ubukhulu bodonga (exp. 4,78 mm)

• Inombolo yobushushu (exp. 138413)

• Umgangatho wemveliso (ASME B16.5)

10. Izinto eziphathekayo aziyi kukhululeka kuzo naziphi na iziphene kunye neentanda.Ukulungiswa kwe-welding akuvumelekanga ngokungqongqo.

11. Zonke iiflange ziya kuphakanyiswa ubuso (RF) kunye nomphezulu wokutywina.Umphezulu wokutywina uya kuba yiRa 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.ukuya ASME B46.1.

12. Izinto eziphathekayo ziya kupakishwa ukukhusela umonakalo kumatshini, kunye nokutywinwa kwendawo.

13. Yonke imilinganiso iya kuba kwi-positive (+) yokunyamezelana.Ukunyamezelwa kweMinus akuvumelekanga ngokungqongqo.

14. Iibevelings zeflange ziya kwenziwa ukuba zihambelane.ukuya ASME B16.25.

15. Inkqubo yokwenziwa kwezinto iya kujongwa nangaliphi na ixesha yi-TPI.

16. I-TPI inokuthatha iisampulu kuyo nayiphi na imathiriyeli yesampulu yovavanyo lwekhemikhali/yomatshini.

17. Ingxelo yohlolo olungenayo iya kuhlolwa yiTPI.

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | IIFLANGE ZETANK | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | IIFLANGE ZETANK | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | IIFLANGE ZETANK | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | IIFLANGE ZETANK | 16 |

| Into | Ubungakanani (Intshi) | Iklasi yoxinzelelo | CS | Izinto eziphathekayo | WT (mm) | Indawo | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Yintoni i-AMSE B16.5 A105 ye-carbon steel butt welding flange?

I-AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flange ibhekisa kuhlobo oluthile lweflange olusetyenziswa kwiinkqubo zombhobho.Yenziwe ngentsimbi yekhabhoni ye-A105 kwaye ibonisa uyilo oludityanisiweyo lwentamo ukubonelela ngokukhuselekileyo, uxhulumaniso lokuvuza.

2. Ziziphi iimpawu eziphambili ze-AMSE B16.5 A105 ezenziwe nge-carbon steel butt welding flange?

Iimpawu eziphambili ze-AMSE B16.5 A105 i-carbon steel butt weld flanges ibandakanya amandla aphezulu, ukuqina kunye nokumelana nokugqwala.Yenzelwe ukumelana noxinzelelo oluphezulu kunye nezicelo zobushushu obuphezulu kwiindawo zoshishino.

3.Ingasetyenziswa phi i-AMSE B16.5 A105 yekhabhoni eyenziwe ngentsimbi yentsimbi yentsimbi?

I-AMSE B16.5 I-A105 eyenziwe nge-carbon steel butt weld flanges isetyenziswa kumashishini ahlukeneyo, kuquka i-oyile kunye negesi, i-petrochemicals, ukuveliswa kwamandla kunye nokunyangwa kwamanzi.Zihlala zisetyenziselwa kwiinkqubo zokubhobhoza ukudibanisa ngokukhuselekileyo iipayipi okanye iivalve.

4. Indlela yokufaka i-AMSE B16.5 A105 ye-carbon steel butt welding flange?

Ukufakela i-AMSE B16.5 A105 ye-carbon steel butt weld flange, okokuqala weld flange kumbhobho okanye ivalve ekupheleni.Intamo ye-weld idityaniswe kwi-flange ehambelanayo komnye umbhobho okanye iqhekeza lesixhobo usebenzisa iibholithi kunye neewasha ukudala uqhagamshelwano oluqinileyo kunye nobungqina bokuvuza.

5. Ziziphi iingenelo zokusebenzisa i-AMSE B16.5 A105 i-carbon steel butt welding flanges?

Ezinye zeenzuzo zokusebenzisa i-AMSE B16.5 A105 i-carbon steel butt weld flanges ibandakanya ukwakhiwa kwayo okuphezulu, okuqinisekisa uxhulumaniso oluthembekileyo noluhlala ixesha elide.Zikwabonelela ngokuhamba kakuhle kolwelo kunye neegesi, ukunciphisa isiphithiphithi, kunye nokunciphisa ukhukuliseko okanye ukubola.

6. Ziziphi iinketho zobungakanani kunye noxinzelelo olukhoyo kwi-AMSE B16.5 A105 ye-carbon steel butt weld flanges?

I-AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flanges zifumaneka kwiindidi ezahlukeneyo zobukhulu, ukusuka kwi-1/2 "ukuya kwi-36" ububanzi.Kwakhona beza kumanqanaba oxinzelelo ahlukeneyo afana ne-150, 300, 600, 900, 1500 kunye ne-2500.

7. Indlela yokuqinisekisa uxhulumaniso olungavuziyo kunye ne-AMSE B16.5 A105 ye-carbon steel butt weld flanges?

Ukuqinisekisa uxhulumaniso olungavuziyo kunye ne-AMSE B16.5 A105 ye-carbon steel butt weld flanges, iiflange kufuneka zihambelane ngokufanelekileyo ngaphambi kokuqinisa iibholithi.I-torque ye-bolt eyaneleyo kufuneka isetyenziswe ngokweenkcukacha ezicetyiswayo ukufezekisa uxhulumaniso olukhuselekileyo nolukhuselekileyo.

8. Ngaba i-AMSE B16.5 A105 i-carbon steel butt weld flanges ingasetyenziselwa uxinzelelo oluphezulu kunye nezicelo eziphezulu zokushisa?

Ewe, i-AMSE B16.5 A105 i-carbon steel butt weld flanges yenzelwe ukujamelana noxinzelelo oluphezulu kunye neemeko eziphezulu zokushisa.Nangona kunjalo, kubalulekile ukuqinisekisa ukuba i-flange kunye namacandelo ahambelanayo ahambelana neemeko ezithile zokusebenza ukuze kugcinwe ukunyaniseka koqhagamshelwano.

9. Ngaba i-AMSE B16.5 A105 ye-carbon steel butt weld flanges ifuna nayiphi na imathiriyeli eyongezelelweyo yokutywina?

Ewe, i-AMSE B16.5 A105 i-carbon steel butt weld flanges ifuna ukusetyenziswa kwee-gaskets ukubonelela ngesitywina phakathi kobuso be-flange.Izinto zeGasket zixhomekeke kuhlobo lolwelo okanye igesi ehanjiswayo kunye neemeko zokusebenza.Ukukhetha imathiriyeli efanelekileyo ye-gasket kubalulekile ekuthinteleni ukuvuza.

10. Ngaba i-AMSE B16.5 A105 i-carbon steel butt welding flanges ifumaneka ngokulula kwimarike?

Ewe, i-AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flange ifumaneka ngokubanzi kwimarike.Ziyintlobo yeflange esetyenziswa ngokuqhelekileyo enokuthengwa kwiintlobo ezahlukeneyo zabathengisi abagunyazisiweyo kunye nabavelisi abaziingcali kwiindibano zemibhobho.

-

Socket weld flange A105 carbon steel SW RTJ 3/4...

-

I-Ansi B16.5 A105 Black Carbon Steel Slip kwiFlange

-

ASME b16.48 Factory Intengiso carbon steel umfanekiso 8 ...

-

orifice flange WN 4″ 900# RF A105 ezimbini gr...

-

I-ASTM A182 F51 F53 BL ANSI B16.5 Intsimbi engatyiwayo...

-

ASME B16.5 BL RF ASTM A182 F316L Stainless stee...