IINKCUKACHA

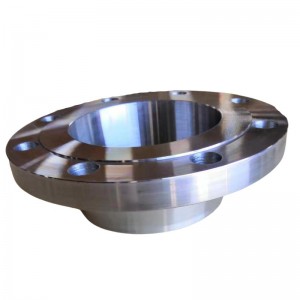

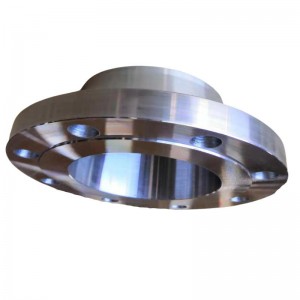

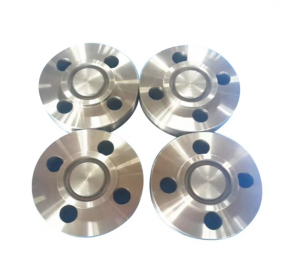

| Igama lemveliso | i-flange yentamo ye-weld |

| Ubungakanani | 1/2"-24" |

| Uxinzelelo | 150#-2500#,PN0.6-PN400,5K-40K |

| Umgangatho | ANSI B16.5,EN1092-1, JIS B2220 njl. |

| Isiphelo sestub | I-MSS SP 43, i-ASME B16.9 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo njl. |

| Intsimbi yekhabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 njl. | |

| Intsimbi engagqwaliyo ephindwe kabini:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njl. | |

| Intsimbi yombhobho:I-A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | |

| I-alloy ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 njl. | |

| I-Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza; umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

IMIGANGATHO YODWALA

IINKCUKACHA ZEMVELISO UMBONO

1. Ubuso

Ingaphakanyiswa ubuso (RF), ubuso obupheleleyo (FF), iRing joint (RTJ), iGroove, ulwimi, okanye yenziwe ngokwezifiso.

2. Isiphelo seBevel ngokwe-ANSI B16.25

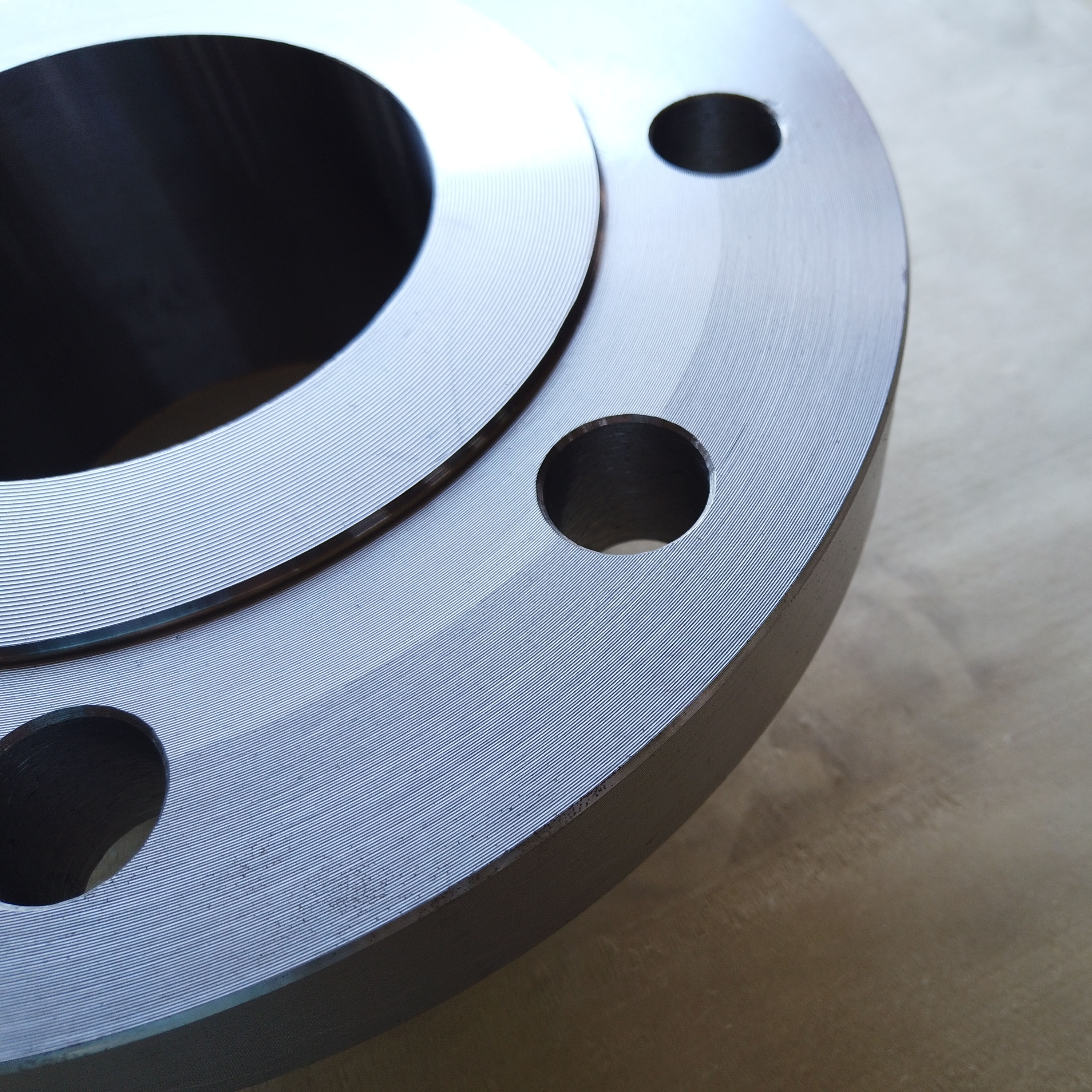

3. I-CNC fine igqityiwe.

Ukugqitywa kobuso: Ukugqitywa kobuso beflange kulinganiswa njengoBude obuPhakathi boBuqatha be-Arithmetical (AARH). Ukugqitywa kugqitywa ngumgangatho osetyenzisiweyo. Umzekelo, i-ANSI B16.5 ichaza ukugqitywa kobuso ngaphakathi koluhlu lwe-125AARH-500AARH (3.2Ra ukuya kwi-12.5Ra). Ezinye ii-finishes ziyafumaneka xa kufunwa, umzekelo i-1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra okanye 6.3/12.5Ra. Uluhlu lwe-3.2/6.3Ra lolona luxhaphakileyo.

UKUPHAKISHA NOKUPAKISHA

• Umaleko ngamnye usebenzisa ifilimu yeplastiki ukukhusela umphezulu

• Kuzo zonke intsimbi engagqwaliyo zipakishwa ngebhokisi yeplywood. Ukuze zibe neflange enkulu yekhabhoni zipakishwa ngepallet yeplywood. Okanye zingenziwa ngokwezifiso ukupakisha.

• Uphawu lokuthumela lungenziwa xa luceliwe

• Iimpawu kwiimveliso zingabanjiswa okanye ziprintwe. I-OEM iyamkelwa.

UVAVANYO

• Uvavanyo lwe-UT

• Uvavanyo lwe-PT

• Uvavanyo lwe-MT

• Uvavanyo lobukhulu

Ngaphambi kokuba ifike, iqela lethu le-QC liza kulungiselela uvavanyo lwe-NDT kunye nokuhlolwa kobukhulu. Kwakhona lamkela i-TPI (ukuhlolwa komntu wesithathu).

INKQUBO YEMVELISO

| 1. Khetha izinto zokwenyani | 2. Sika izinto ezikrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Umatshini Onzima |

| 7. Ukubhola | 8. Ukuluka kakuhle | 9. Ukumakisha |

| 10. Uhlolo | 11. Ukupakisha | 12. Ukuhanjiswa |

ITYALA LENTSEBENZISWANO

Iprojekthi eseTurkey, iiflanges zisetyenziswa kwimibhobho yegesi yendalo. Zonke ezo flanges zivunyiwe yiTUV.

IPHEPHA LEDATHA YEFLANGE

1Ubukhulu beFlange kunye nokunyamezelana kwayo kufuneka kuhambelane ne-ASME B16.5.

2. Iiflanges maziveliswe ngokubumba.

3. Izixhobo mazihambelane nemigangatho ye-ASTM A105, ASTM A694 F65 kunye ne-ASTM A694 F70.

4. Iiflange ze-ASTM A694 F65 kunye ne-ASTM A694 F70 mazicinywe kwaye ziqiniswe.

5. Izatifikethi zovavanyo lwezinto kunye neengxelo zonyango lobushushu ziya kwenziwa zifumaneke kuhlolo lwe-TPI.

6. Iiflange zeWN mazibe neziphelo ze-bevel ezifikelela kwi-ASME B16.25.

7. Amaxabiso ovavanyo lweekhemikhali kunye noomatshini (impembelelo, isivuno, ukuxinana njl.njl.) kufuneka ahambelane nemigangatho enxulumene noko.

8. Zonke iindawo kufuneka zicocwe ngomatshini kwaye zifakwe ivarnish ngeoyile ecacileyo ukuthintela ukugqwala.

9. Ukumakisha kufuneka kuquka olu lwazi lulandelayo,

• Ububanzi (ixesha eliphela ngo-6”)

• Udidi loxinzelelo (oluphelelwa yi-150 LB)

• Udidi lwezinto (ukuphelelwa yi-ASTM A 105)

• Ubukhulu bodonga (ngaphandle kwe-4,78 mm)

• Inombolo yobushushu (iphelelwa lixesha 138413)

• Umgangatho wemveliso (ASME B16.5)

10. Izinto azinaziphene okanye ziqhekeke kumphezulu. Ukulungiswa kwee-welding akuvumelekanga ngokupheleleyo.

11. Zonke iiflanges maziphakanyiswe ubuso (RF) kunye nomphezulu wokutywina. Umphezulu wokutywina kufuneka ube yiRa 3,2 – 6,3 µm (125 – 250 mic. inc.) acc. kwi-ASME B46.1.

12. Izinto kufuneka zipakishwe ukuze kuthintelwe umonakalo kwimishini, nakwindawo ezitywiniweyo.

13. Zonke izilinganiso mazibe kwimilinganiselo emihle (+). Ukunciphisa ukunyamezelana akuvumelekanga ngokupheleleyo.

14. Iibheveling zeFlange mazifakwe kwi-ASME B16.25.

15. Inkqubo yokuvelisa iya kuhlolwa nangaliphi na ixesha yi-TPI.

16. I-TPI ingathatha iisampulu kuyo nayiphi na into ukuze kwenziwe isampuli yovavanyo lweekhemikhali/yoomatshini.

17. Ingxelo yohlolo engenayo iya kuhlolwa yi-TPI.

| Into | Ubungakanani (Inch) | Iklasi yoXinzelelo | CS | Izinto eziphathekayo | Ubunzima (mm) | Indawo | Ubungakanani. |

| I-SORF | 12 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 48 |

| I-SORF | 8 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 32 |

| I-SORF | 3 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 32 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 14 | IIFANGES ZETANKI | 2 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 5.54 | IIFANGES ZETANKI | 4 |

| I-SORF | 20 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 6 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 5.54 | IIFANGES ZETANKI | 8 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 14 | IIFANGES ZETANKI | 8 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 16 | IIFANGES ZETANKI | 8 |

| I-SORF | 3 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 24 |

| I-SORF | 20 | 150LB | 20 | A105 | - | IIFANGES ZETANKI | 6 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 5.54 | IIFANGES ZETANKI | 8 |

| I-Flange, Intamo yeWeld | 24 | 150LB | 20 | A105 | 14 | IIFANGES ZETANKI | 16 |

| Into | Ubungakanani (Inch) | Iklasi yoXinzelelo | CS | Izinto eziphathekayo | Ubunzima (mm) | Indawo | Ubungakanani. |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo yeWeld | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo yeWeld | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo yeWeld | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo yeWeld | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo yeWeld | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 2 |

| I-Flange, Intamo yeWeld | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 6 |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 4 |

| I-Flange, Intamo yeWeld | 20 | 400LB | 62 | I-ASTM A694 F70 | 7.14 | I-PSM1 | 10 |

| I-Flange, Intamo yeWeld | 12 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 4 |

| I-Flange, Intamo yeWeld | 24 | 400LB | 62 | I-ASTM A694 F70 | 7.92 | I-PSM1 | 25 |

| I-Flange, Intamo yeWeld | 4 | 400LB | 62 | I-ASTM A694 F70 | 4.78 | I-PSM1 | 16 |

| I-Flange, Intamo yeWeld | 10 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | I-PSB1 | 2 |

| I-Flange, Intamo yeWeld | 6 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo yeWeld | 4 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 4 |

| I-Flange, Intamo yeWeld | 18 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo yeWeld | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

| I-Flange, Intamo yeWeld | 8 | 300LB | 51 | I-ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Yintoni i-AMSE B16.5 A105 eyenziwe nge-carbon steel butt welding flange?

I-AMSE B16.5 A105 I-Forged Carbon Steel Butt Weld Flange ibhekisa kuhlobo oluthile lweflange esetyenziswa kwiinkqubo zemibhobho. Yenziwe ngentsimbi yekhabhoni ye-A105 kwaye inoyilo lwentamo edibeneyo ukubonelela ngonxibelelwano olukhuselekileyo nolungenako ukuvuza.

2. Ziziphi iimpawu eziphambili ze-AMSE B16.5 A105 forged carbon steel butt welding flange?

Iimpawu eziphambili ze-AMSE B16.5 A105 forged carbon steel butt weld flanges ziquka amandla aphezulu, ukuqina kunye nokumelana nokugqwala. Yenzelwe ukumelana noxinzelelo oluphezulu kunye nokusetyenziswa kobushushu obuphezulu kwiindawo zoshishino.

3. Ingasetyenziswa phi i-AMSE B16.5 A105 forged carbon steel butt welding flange?

Iiflange ze-AMSE B16.5 A105 ze-carbon steel butt weld ezibunjiweyo zisetyenziswa kumashishini ahlukeneyo, kuquka ioyile negesi, iikhemikhali zepetroli, ukuveliswa kombane kunye nonyango lwamanzi. Zihlala zisetyenziswa kwiinkqubo zemibhobho ukuqhagamshela imibhobho okanye iivalvu ngokukhuselekileyo.

4. Uyifaka njani i-AMSE B16.5 A105 forged carbon steel butt welding flange?

Ukufakela i-flange ye-AMSE B16.5 A105 eyenziwe nge-carbon steel butt weld, qala ngokuyitshixa i-flange uye kumbhobho okanye kwisiphelo sevalvu. Intamo ye-weld emva koko iqhagamshelwe kwi-flange ehambelanayo kwenye ipayipi okanye isixhobo kusetyenziswa iibholiti kunye neewashers ukwenza uqhagamshelo oluqinileyo nolungenako ukuvuza.

5. Ziziphi iingenelo zokusebenzisa iiflange ze-AMSE B16.5 A105 ze-carbon steel butt welding?

Ezinye zeenzuzo zokusebenzisa iiflange ze-AMSE B16.5 A105 ze-carbon steel butt weld ziquka ukwakhiwa kwazo okunamandla aphezulu, okuqinisekisa uqhagamshelo oluthembekileyo noluhlala ixesha elide. Zikwabonelela ngokuhamba kakuhle kolwelo kunye neegesi, zinciphise ukuxinana, kwaye zinciphise ukukhukuliseka okanye ukugqwala.

6. Ziziphi iindlela zokulinganisa ubungakanani kunye noxinzelelo ezikhoyo kwiiflange ze-AMSE B16.5 A105 ze-carbon steel butt weld?

Iiflanges ze-AMSE B16.5 A105 zeForged Carbon Steel Butt Weld ziyafumaneka ngobukhulu obahlukeneyo, ukusuka kwi-1/2" ukuya kwi-36" ububanzi. Zikwaza namanqanaba oxinzelelo ahlukeneyo afana ne-150, 300, 600, 900, 1500 kunye ne-2500.

7. Ungaqinisekisa njani ukuba unxibelelwano olungenamanzi lufumaneka kwiiflange ze-AMSE B16.5 A105 ze-carbon steel butt weld?

Ukuqinisekisa uqhagamshelo olungenamanzi kunye neeflange ze-AMSE B16.5 A105 ze-carbon steel butt weld, iiflange kufuneka zilungelelaniswe kakuhle ngaphambi kokuba ziqiniswe iibholithi. Kufuneka kusetyenziswe i-torque eyaneleyo yebholithi ngokweemfuno ezicetyisiweyo ukuze kufunyanwe uqhagamshelo olukhuselekileyo nolukhuselekileyo.

8. Ngaba ii-flanges ze-AMSE B16.5 A105 ze-carbon steel butt weld ezifakelweyo zingasetyenziswa kwiindlela zoxinzelelo oluphezulu kunye nobushushu obuphezulu?

Ewe, iiflange ze-AMSE B16.5 A105 ezenziwe nge-carbon steel butt weld zenzelwe ukumelana noxinzelelo oluphezulu kunye neemeko zobushushu obuphezulu. Nangona kunjalo, kubalulekile ukuqinisekisa ukuba iflange kunye nezinto ezinxulumene nayo ziyahambelana neemeko ezithile zokusebenza ukugcina ukuthembeka koqhagamshelo.

9. Ngaba iiflange ze-AMSE B16.5 A105 ze-carbon steel butt weld ezifakelweyo zifuna naziphi na izinto ezongezelelweyo zokutywina?

Ewe, iiflange ze-AMSE B16.5 A105 ezifakelwe i-carbon steel butt weld zifuna ukusetyenziswa kwee-gaskets ukuze kubekho itywina phakathi kobuso be-flange. Izinto ze-gasket zixhomekeke kuhlobo lolwelo okanye igesi ehanjiswayo kunye neemeko zokusebenza. Ukukhetha izinto ze-gasket ezifanelekileyo kubalulekile ekuthinteleni ukuvuza.

10. Ngaba iiflange zokuwelda ze-AMSE B16.5 A105 ezenziwe ngekhabhoni zifumaneka lula kwimarike?

Ewe, i-AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flange ifumaneka kakhulu kwimarike. Luhlobo lweflange olusetyenziswa rhoqo olunokuthengwa kubathengisi abahlukeneyo abagunyazisiweyo kunye nabavelisi abagxile kwiindibano zepayipi.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

i-flange ye-orifice WN 4″ 900# RF A105 ezimbini gr ...

-

I-Ansi B16.5 A105 Black Carbon Steel Slip kwiFlange

-

I-flange ye-weld yesokhethi i-A105 carbon steel SW RTJ 3/4 ...

-

i-flange ye-asme b16.36 wn eyenziwe nge-orifice ene-Jack ...

-

I-ASME B16.5 BL RF ASTM A182 F316L Intsimbi engenasici ...

-

I-304 Stainless Steel Flanged Custom High Quality ...