IIPARAMETHA ZEMVELISO

| Igama lemveliso | Isiciko sepayipi |

| Ubungakanani | I-1/2"-60" engenamthungo, i-60"-110" edityanisiweyo |

| Umgangatho | I-ANSI B16.9, EN10253-4, DIN2617, GOST17379, JIS B2313, MSS SP 75, njl. |

| Ubukhulu bodonga | I-SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, eyenziwe ngokwezifiso kwaye njl. |

| Isiphelo | Isiphelo seBevel/BE/buttweld |

| Umphezulu | i-pickled, i-sand rolling, i-polished, i-mirror polishing njalo njalo. |

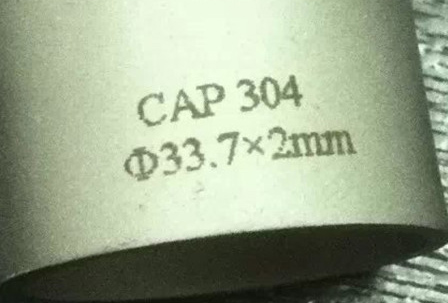

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo njalo njalo. |

| Intsimbi engagqwaliyo ephindwe kabini:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njl. | |

| I-alloy ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, iMonel400, iAlloy20 njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza, umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

ISIQHOBO SEMPI YENTSIMBI

I-Steel Pipe Cap ikwabizwa ngokuba yiSteel Plug, idla ngokudityaniswa kwisiphelo sepayipi okanye ifakwe kwintambo yangaphandle yesiphelo sepayipi ukuze igqume izixhobo zepayipi. Ukuvala umbhobho ukuze umsebenzi ufane ne-pipe plug.

UHLOBO LWESIQEPHU

Kukho iintlobo zoqhagamshelo: 1. Isivalo se-Butt weld 2. Isivalo se-Socket weld

Ikepusi yentsimbi yeBW

Isivalo sentsimbi se-BW luhlobo lwe-butt weld lwezixhobo, iindlela zokudibanisa kukusebenzisa i-butt welding. Ngoko ke isivalo se-BW siphela nge-beveled okanye i-plain.

Ubukhulu kunye nobunzima besiciko se-BW:

| Ubungakanani bepayipi eqhelekileyo | Ububanzi obungaphandle beBevel(mm) | UbudeE(mm) | Ukunciphisa Ubukhulu Bodonga Lobude, E | UbudeE1(mm) | Ubunzima (kg) | |||||

| I-SCH10S | I-SCH20 | Izifo ezithathelwana ngesondo (STD) | I-SCH40 | XS | I-SCH80 | |||||

| 1/2 | 21.3 | 25 | 4.57 | 25 | 0.04 | 0.03 | 0.03 | 0.05 | 0.05 | |

| 3/4 | 26.7 | 25 | 3.81 | 25 | 0.06 | 0.06 | 0.06 | 0.10 | 0.10 | |

| 1 | 33.4 | 38 | 4.57 | 38 | 0.09 | 0.10 | 0.10 | 0.013 | 0.13 | |

| 1 1/4 | 42.2 | 38 | 4.83 | 38 | 0.13 | 0.14 | 0.14 | 0.20 | 0.20 | |

| 1 1/2 | 48.3 | 38 | 5.08 | 38 | 0.14 | 0.20 | 0.20 | 0.23 | 0.23 | |

| 2 | 60.3 | 38 | 5.59 | 44 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | |

| 2 1/2 | 73 | 38 | 7.11 | 51 | 0.30 | 0.20 | 0.50 | 0.50 | 0.50 | |

| 3 | 88.9 | 51 | 7.62 | 64 | 0.45 | 0.70 | 0.70 | 0.90 | 0.90 | |

| 3 1/2 | 101.6 | 64 | 8.13 | 76 | 0.60 | 1.40 | 1.40 | 1.70 | 1.70 | |

| 4 | 114.3 | 64 | 8.64 | 76 | 0.65 | 1.6 | 1.6 | 2.0 | 2.0 | |

| 5 | 141.3 | 76 | 9.65 | 89 | 1.05 | 2.3 | 2.3 | 3.0 | 3.0 | |

| 6 | 168.3 | 89 | 10.92 | 102 | 1.4 | 3.6 | 3.6 | 4.0 | 4.0 | |

| 8 | 219.1 | 102 | 12.70 | 127 | 2.50 | 4.50 | 5.50 | 5.50 | 8.40 | 8.40 |

| 10 | 273 | 127 | 12.70 | 152 | 4.90 | 7 | 10 | 10 | 13.60 | 16.20 |

| 12 | 323.8 | 152 | 12.70 | 178 | 7 | 9 | 15 | 19 | 22 | 26.90 |

| 14 | 355.6 | 165 | 12.70 | 191 | 8.50 | 15.50 | 17 | 23 | 27 | 34.70 |

| 16 | 406.4 | 178 | 12.70 | 203 | 14.50 | 20 | 23 | 30 | 30 | 43.50 |

| 18 | 457 | 203 | 12.70 | 229 | 18 | 25 | 29 | 39 | 32 | 72.50 |

| 20 | 508 | 229 | 12.70 | 254 | 27.50 | 36 | 36 | 67 | 49 | 98.50 |

| 22 | 559 | 254 | 12.70 | 254 | 42 | 42 | 51 | 120 | ||

| 24 | 610 | 267 | 12.70 | 305 | 35 | 52 | 52 | 93 | 60 | 150 |

IIFOWUNI EZINIKA INKCAZELO

1. Isiphelo se-Bevel ngokwe-ANSI B16.25.

2. Ipolishi erhabaxa kuqala ngaphambi kokuba iqengqeleke isanti, emva koko umphezulu uya kuba mpuluswa kakhulu.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Ngaphandle kokulungiswa kwe-weld.

5. Ukulungiswa komphezulu kunokucolwa, ukuqengqeleka kwesanti, ukugqitywa kwe-matt, ukupholishwa kwesipili. Ngokuqinisekileyo, ixabiso lahlukile. Ngokwesalathiso sakho, umphezulu wokuqengqeleka kwesanti ngowona udumileyo. Ixabiso le-sand roll lifanelekile kubathengi abaninzi.

UVAVANYO

1. Ubungakanani bokulinganisa, konke kuxhomekeke ekunyamezeleni okuqhelekileyo.

2. Ukunyamezelana kobukhulu: +/-12.5%, okanye ngokwesicelo sakho.

3. I-PMI

4. Uvavanyo lwe-PT, UT, kunye ne-X-ray.

5. Yamkela uhlolo lomntu wesithathu.

6. Isiqinisekiso se-MTC, i-EN10204 3.1/3.2, i-NACE

7. I-ASTM A262 yokuziqhelanisa E

UKUPHAWULA

Imisebenzi eyahlukeneyo yokumakisha ingabakho xa ucela. Siyayamkela i-LOGO yakho.

FAQ

1. Yintoni isigqubuthelo sesitya soxinzelelo sepayipi esitshixiweyo sentsimbi engagqwaliyo?

Isigqubuthelo sesitya soxinzelelo sepayipi esitshisiweyo ngentsimbi engagqwaliyo sisixhobo esisetyenziselwa ukuvala iziphelo zemibhobho yesitya soxinzelelo edityaniswe ngokutshiza. Senziwe ngentsimbi engagqwaliyo, siqinisekisa ukuqina kunye nokumelana nokugqwala.

2. Ziziphi iingenelo zokusebenzisa izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo?

Ukusetyenziswa kwezigqubuthelo zemibhobho yoxinzelelo lwentsimbi engagqwaliyo kuneenzuzo zokuba namandla aphezulu, ukumelana noxinzelelo oluphezulu, ukumelana nobushushu obuphezulu, kunye nokumelana nokugqwala. Kuqinisekisa ukutywinwa okukhuselekileyo kwaye kunceda ukugcina ukuthembeka kwenqanawa yoxinzelelo.

3. Ungasifaka njani isigqubuthelo sesitya soxinzelelo sentsimbi engagqwali esidityaniswe ngentsimbi engagqwali?

Ukuze ufakele isigqubuthelo sesitya soxinzelelo sentsimbi engagqwaliyo, sebenzisa iindlela ezifanelekileyo zokuwelda ukuwelda isigqubuthelo ukuya esiphelweni sombhobho wesitya soxinzelelo. Kubalulekile ukuqinisekisa ukulungelelaniswa okufanelekileyo kunye nokuwelda okuqinileyo ukuze kutywinwe ngendlela ethembekileyo.

4. Ngaba izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo ziyafumaneka ngobukhulu obahlukeneyo?

Ewe, izigqubuthelo zesitya soxinzelelo semibhobho esitshixiweyo sentsimbi engagqwaliyo ziyafumaneka ngobukhulu obahlukeneyo ukuze zilungele ububanzi beepayipi ezahlukeneyo. Ukukhetha ubungakanani obufanelekileyo ukuqinisekisa ukuba ilingana kwaye itywinwe ngokufanelekileyo kubalulekile.

5. Ngaba izigqubuthelo zesitya soxinzelelo lwemibhobho esitshisiweyo ngentsimbi engagqwaliyo zingasetyenziswa kwiindawo ezinoxinzelelo oluphezulu?

Ewe, izigqubuthelo zesitya soxinzelelo lwemibhobho ezitshixiweyo ngentsimbi engagqwaliyo zenzelwe ukumelana nokusetyenziswa koxinzelelo oluphezulu. Zenzelwe ukumelana namandla abangelwa luxinzelelo olungaphakathi kwisikhongozeli kwaye zigcine itywina liqinile.

6. Ngaba isigqubuthelo sombhobho ocinezelweyo wentsimbi engagqwaliyo asimelani nokugqwala?

Ewe, izigqubuthelo zemibhobho yoxinzelelo lwentsimbi engagqwaliyo edityaniswe ngentsimbi engagqwaliyo ziyakwazi ukumelana nokugqwala kakhulu. Intsimbi engagqwaliyo yaziwa ngeempawu zayo zokumelana nokugqwala, nto leyo eyenza ukuba ifaneleke kwiintlobo ngeentlobo zezicelo zoshishino.

7. Ngaba izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo zingasetyenziswa kwiintlobo ezahlukeneyo zesitya soxinzelelo?

Ewe, izigqubuthelo zemibhobho yoxinzelelo ezifakwe ngentsimbi engagqwaliyo zinokusetyenziswa ngeendlela ezahlukeneyo kwaye zingasetyenziswa kwiindidi ezahlukeneyo zemibhobho yoxinzelelo, kuquka ezo zisetyenziswa kwimizi-mveliso yeoyile negesi, iikhemikhali kunye namayeza.

8. Ingakanani ixesha lenkonzo yesigqubuthelo sesitya soxinzelelo sepayipi esitshixiweyo sentsimbi engagqwali?

Ubomi benkonzo yezigqubuthelo zesinyithi eziwelsiweyo zepayipi eziphelweni zoxinzelelo lwesitya buxhomekeke kwizinto ezifana neemeko zokusetyenziswa kwesigqubuthelo, ukugcinwa kunye nomgangatho. Ngokugcinwa ngokufanelekileyo kunye nokuhlolwa rhoqo, zinokuhlala iminyaka emininzi.

9. Ngaba kukho naziphi na iindlela zokhuseleko ezithile xa usebenzisa izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo?

Xa usebenzisa izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo, kufuneka kulandelwe amanyathelo okhuseleko, njengokusebenzisa iindlela ezifanelekileyo zokutywina ukuqinisekisa ukuvalwa okuqinileyo nokungavuzi. Ukuqinisekisa ukhuseleko, kufuneka ujonge rhoqo iimpawu zokuguguleka okanye zokonakala.

10. Ngaba isigqubuthelo sesitya soxinzelelo sepayipi esitshisiweyo sentsimbi engagqwali singenziwa ngokwezifiso?

Ewe, kuxhomekeke kumenzi, izigqubuthelo zesitya soxinzelelo semibhobho esitshisiweyo ngentsimbi engagqwaliyo zinokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile. Iindlela zokwenza ngokwezifiso zingabandakanya izixhobo ezahlukeneyo, ubungakanani kunye noyilo oluhambelana nezicelo zomntu ngamnye.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

I-ASME B16.9 A105 A234WPB Intsimbi yeCarbon eneempundu zentsimbi ...

-

Intsimbi Engagqwaliyo A403 WP316 Butt Weld Pipe Fitti ...

-

isiphelo se-carbon steel sch80 butt welded 12 intshi sch4 ...

-

intsimbi yekhabhoni i-concentric reducer ASTM A105 Black ...

-

I-90 degree engqinibeni tee reducer carbon steel Butt w ...

-

Ipayipi yengqiniba eyi-1″ 33.4mm DN25 25A sch10 ifanelekile ...