Iingcebiso

Ivalvu yenaliti esemgangathweni ophezulu ingasebenza ngesandla okanye ngokuzenzekelayo. Iivalvu zenaliti ezisetyenziswa ngesandla zisebenzisa ivili lesandla ukulawula umgama phakathi kweplunger kunye nesihlalo sevalvu. Xa ivili lesandla lijikeleziswa kwicala elinye, iplunger iyaphakanyiswa ukuvula ivalvu kwaye ivumele ulwelo ukuba ludlule. Xa ivili lesandla lijikeleziswa kwelinye icala, iplunger isondela kwisihlalo ukuze yehlise isantya sokuhamba okanye ivale ivalvu.

Iivalvu zeenaliti ezizenzekelayo ziqhagamshelwe kwi-hydraulic motor okanye kwi-air actuator evula kwaye ivale i-valve ngokuzenzekelayo. I-motor okanye i-actuator iya kulungisa indawo ye-plunger ngokwee-timers okanye idatha yokusebenza yangaphandle eqokelelwe xa kubekwa esweni oomatshini.

Zombini iivalvu zenaliti ezisebenza ngesandla nezizenzekelayo zibonelela ngolawulo oluchanekileyo lwesantya sokuhamba kwamanzi. Ivili lesandla lifakwe imisonto emincinci, oko kuthetha ukuba kuthatha ukujika okuphindaphindiweyo ukulungisa indawo ye-plunger. Ngenxa yoko, ivalvu yenaliti inokukunceda ulawule ngcono isantya sokuhamba kolwelo kwinkqubo.

Iimpawu zeValve yenaliti Izinto kunye nemifanekiso

1. Ivalvu yenaliti

2. Yenziwe ngentsimbi engenasici i-ASTM A479-04 (iBanga 316)

3. Iziphelo ezinemisonto ngokwe-ASME B 1.20.1(NPT)

4. Uxinzelelo oluphezulu lokusebenza yi-6000 psi kwi-38 °C

5.Ubushushu obusebenzayo -54 ukuya kuma-232°C

6. Isitshixo sebhonethi yokhuseleko sithintela ukulahleka ngengozi.

7. Uyilo lwezihlalo ezingasemva lukhusela ukupakisha kwindawo evulekileyo ngokupheleleyo.

| N° | Igama | Izinto eziphathekayo | Unyango Lomphezulu |

| 1 | Isibambo se-Grib Scres | SS316 | |

| 2 | Phatha | SS316 | |

| 3 | Isiqu soMngxuma | SS316 | Unyango lweNitrogen |

| 4 | Isivalo sothuli | Iplastiki | |

| 5 | Ukupakisha i-nut | SS316 | |

| 6 | I-Tshixa Nut | SS316 | |

| 7 | Ibhonethi | SS316 | |

| 8 | Umtshisi wokuhlamba impahla | SS316 | |

| 9 | Ukupakisha Isiqu | I-PTFE + iGraphite | |

| 10 | Ukuhlamba | SS316 | |

| 11 | Tshixa iPhini | SS316 | |

| 12 | Indandatho ye-O | FKM | |

| 13 | Umzimba | Ibanga 316 |

Iinaliti zeValve zobukhulu obuqhelekileyo

| Ireferensi | Ubungakanani | I-PN(psi) | E | H | L | M | K | Ubunzima(Kg) |

| 225N 02 | 1/4" | 6000 | 25.5 | 90 | 61 | 55 | 4 | 0.365 |

| 225N 03 | 3/8" | 6000 | 25.5 | 90 | 61 | 55 | 4 | 0.355 |

| 225N 04 | 1/2" | 6000 | 28.5 | 92 | 68 | 55 | 5 | 0.440 |

| 225N 05 | 3/4" | 6000 | 38 | 98 | 76 | 55 | 6 | 0.800 |

| 225N 06 | 1" | 6000 | 44.5 | 108 | 85 | 55 | 8 | 1.120 |

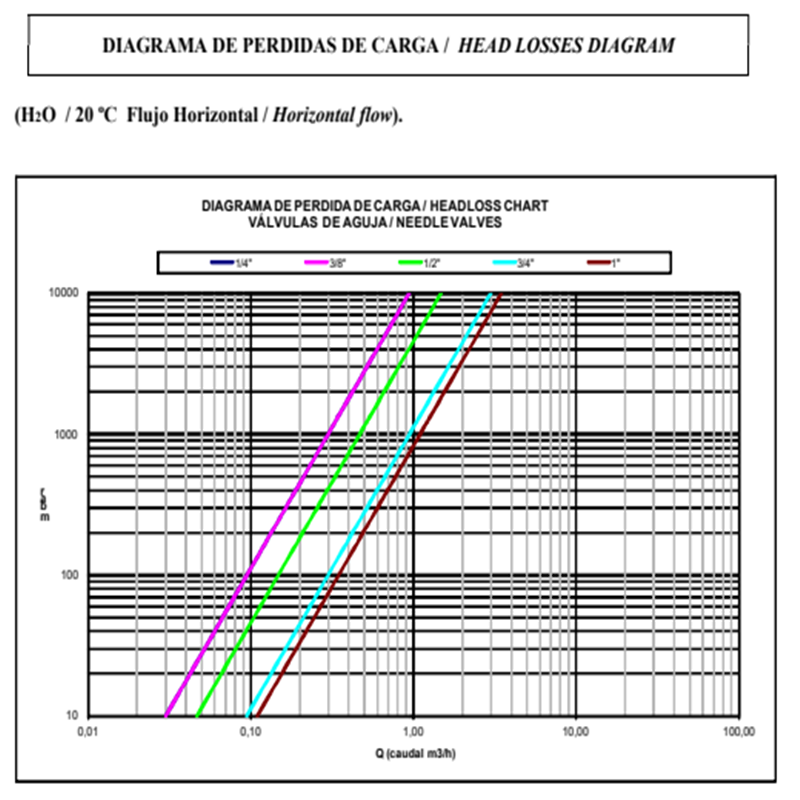

Umzobo wokulahlekelwa yiNtloko yeValve yeNgwele

Iivalvu zenaliti Uvavanyo lobushushu boxinzelelo

IXABISO LE-Kv

I-KV = Isantya sokuhamba kwamanzi kwi-cubic meter ngeyure (m³/h) eya kuvelisa ukuhla koxinzelelo lwebha enye kwivalvu.

| ubungakanani | 1/4" | 3/8" | 1/2" | 3/4" | 1" |

| m³/h | 0.3 | 0.3 | 0.63 | 0.73 | 1.4 |

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.