Iivalvu zesango zisetyenziselwa ukuvala ukuhamba kolwelo endaweni yokulawula ukuhamba kolwelo. Xa luvuliwe ngokupheleleyo, ivalvu yesango eqhelekileyo ayinangxaki kwindlela yokuhamba kolwelo, nto leyo ebangela ukuba kubekho ukumelana okuphantsi kakhulu kokuhamba kolwelo. Ubungakanani bendlela yokuhamba kolwelo evulekileyo buhlala buhluka ngendlela engeyomgca njengoko isango lishukunyiswa. Oku kuthetha ukuba izinga lokuhamba kolwelo alitshintshi ngokulinganayo ngokuhamba kwesiqu. Ngokuxhomekeke kulwakhiwo, isango elivulekileyo kancinci linokunyakaza ngenxa yokuhamba kolwelo.

Iimpawu zoYilo

- Isikrufu kunye neYoke yangaphandle (OS&Y)

- I-Two Piece self aligning packing gland

- Ibhonethi enebholti ene-gasket ene-spiral-wound

- Isihlalo esingasemva esidibeneyo

Iinkcukacha

- Uyilo oluSisiseko: API 602, ANSI B16.34

- Isiphelo ukuya esiphelweni: Umgangatho we-DHV

- Uvavanyo kunye noHlolo: API-598

- Iziphelo Ezinezikrufu (NPT) ukuya kwi-ANSI/ASME B1.20.1

- Isiphelo se-Socket weld ukuya kwi-ASME B16.11

- Ukuwelda kweempundu kuphelela kwi-ASME B16.25

- Isiphelo seFlange: ANSI B16.5

Iimpawu eziKhethekileyo

- Intsimbi Ephosiweyo, Intsimbi Edibeneyo, Intsimbi Engagqwaliyo

- Izibuko elipheleleyo okanye izibuko eliqhelekileyo

- Isiqu Esandisiweyo okanye Ngaphantsi Kwesitywina

- Ibhonethi eWelded okanye iBhonethi yeTywina yoXinzelelo

- Ukutshixa isixhobo xa siceliwe

- Ukwenziwa kwemveliso kwi-NACE MR0175 xa iceliwe

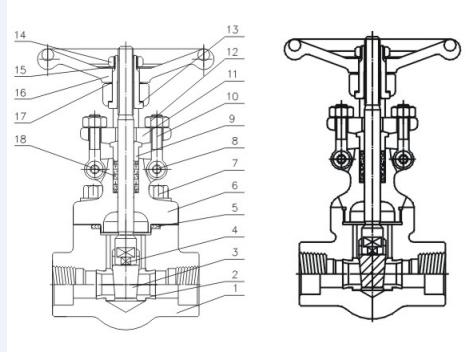

Umzobo weeMveliso

Imigangatho yoSetyenziso

1.Uyilo kunye nokuveliswa kuhambelana ne-API 602, BS5352, ANSI B 16.34

2. Uqhagamshelo luphela ngokusuka ku:

1) Ubukhulu be-weld yesokhethi buhambelana ne-ANSI B 16.11, JB/T 1751

2) Iziphelo zesikrufu zihambelana ne-ANSI B 1.20.1, JB/T 7306

3) I-Butt-Welded ihambelana ne-ANSI B16.25, JB/T12224

4) Iziphelo ezijikelezileyo zihambelana ne-ANSI B 16.5, JB79

3. Uvavanyo kunye nokuhlolwa kuyavumelana:

1) I-API 598, GB/T 13927, JB/T9092

4. Iimpawu zesakhiwo:

Ibhonethi enebholti, isikrufu sangaphandle kunye nejoko

Ibhonethi edibeneyo, izikreyi zangaphandle kunye nejoko

5. Izinto ezisetyenziswayo zihambelana ne-ANSI/ASTM

6. Izinto eziphambili:

A105,LF2,F5,F11,F22,304(L),316(L),F347,F321,F51,Monel,20Alloy

Intsimbi yekhabhoni Izinga lobushushu noxinzelelo

CL150-285 PSI@ 100°F

CL300-740 PSI@ 100°F

CL600-1480 PSI@ 100°F

CL800-1975 PSI@ 100°F

CL1500-3705 PSI@ 100°F

Uluhlu lwezinto eziphambili

| NO | Igama leCandelo | A105/F6a | I-A105/F6a HFS | LF2/304 | F11/F6AHF | F304(L) | F316(L) | F51 |

| 1 | Umzimba | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F51 |

| 2 | Isihlalo | 410 | 410HF | 304 | 410HF | 304(L) | 316(L) | F51 |

| 3 | I-Wedge | F6a | F6a | F304 | F6aHF | F304(L) | F306(L) | F51 |

| 4 | Isiqu | 410 | 410 | 304 | 410 | 304(L) | 316(L) | F51 |

| 5 | I-Gasket | I-Graphite eguquguqukayo engama-304+ | I-Graphite eguquguqukayo engama-304+ | I-Graphite eguquguqukayo engama-304+ | I-Graphite eguquguqukayo engama-304+ | I-Graphite eguquguqukayo engama-304+ | I-Graphite eguquguqukayo engama-316+ | I-Graphite eguquguqukayo engama-316+ |

| 6 | Ibhonethi | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F51 |

| 7 | Ibholti | B7 | b7 | L7 | B16 | B8(M) | B8(M) | B8(M) |

| 8 | Phina | 410 | 410 | 410 | 410 | 304 | 304 | 304 |

| 9 | Indlala | 410 | 410 | 304 | 410 | 304 | 316 | F51 |

| 10 | I-Gland eyebolt | B7 | B7 | L7 | B16 | B8M | B8M | B8M |

| 11 | I-Gland Flange | A105 | A105 | LF2 | F11 | F304 | F304 | F304 |

| 12 | I-Hex nut | 2H | 2H | 2H | 2H | 8M | 8M | 8M |

| 13 | I-Stem nut | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 14 | I-nut yokutshixa | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| 15 | Ipleyiti yegama | AL | AL | AL | AL | AL | AL | AL |

| 16 | Ivili lesandla | A197 | A197 | A197 | A197 | A197 | A197 | A197 |

| 17 | I-GricatingGasket | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| 18 | Ukupakisha | Igrafayithi | Igrafayithi | Igrafayithi | Igrafayithi | Igrafayithi | Igrafayithi | Igrafayithi |

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.