I-Flange ye-Orifice ye-ASME B16.36 WN eyenziwe nge-Forged ene-Jack Screw

I-Forged ASME B16.36 Weld Neck Orifice Flange eneJack Screw imele icandelo lokulinganisa ukuhamba okuchanekileyo eliyilwe ngokweenkqubo ezibalulekileyo kumacandelo emizi-mveliso afuna izinto ezininzi. Le flange ikhethekileyo idibanisa itekhnoloji yokubumba ephucukileyo kunye neempawu zoyilo ezisebenzayo ukuqinisekisa ukusebenza ngokuchanekileyo, okuthembekileyo, nokukhuselekileyo kwiinkqubo zoxinzelelo oluphezulu kunye nobushushu obuphezulu. Yenziwe ngokuhambelana ngokungqongqo nemigangatho ye-ASME B16.36 kunye ne-B16.5, isebenza njengecandelo elibalulekileyo kwiinkqubo zokulinganisa nokulawula ulwelo.

IINKCUKACHA

| Igama lemveliso | intamo ye-weld Orifice flange | |||

| USAYIZI | 1" phezulu 24" | |||

| Uxinzelelo | 150#-2500# | |||

| Umgangatho | I-ANSI B16.36 | |||

| Ubukhulu bodonga | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS kunye njl. | |||

| Izinto eziphathekayo | Intsimbi engagqwaliyo: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo kunye nokunye. Intsimbi yekhabhoni: A105, A350LF2, Q235, St37, St45.8, A42CP, E24, A515 Gr60, A515 Gr 70 | |||

| Intsimbi engagqwaliyo ephindwe kabini: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, I-UNS32760, 1.4462,1.4410,1.4501 kunye nezinye. Intsimbi yombhobho: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 njl. | ||||

| I-alloy yeNickel: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 njl. I-Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 njl. | ||||

| Isicelo | ishishini le-Petrochemical; ishishini le-avation kunye ne-aerospace; ishishini le-pharmaceutical; umphunga wegesi; isikhululo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. | |||

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu | |||

IMIGANGATHO YODWALA

IINKCUKACHA ZEMVELISO

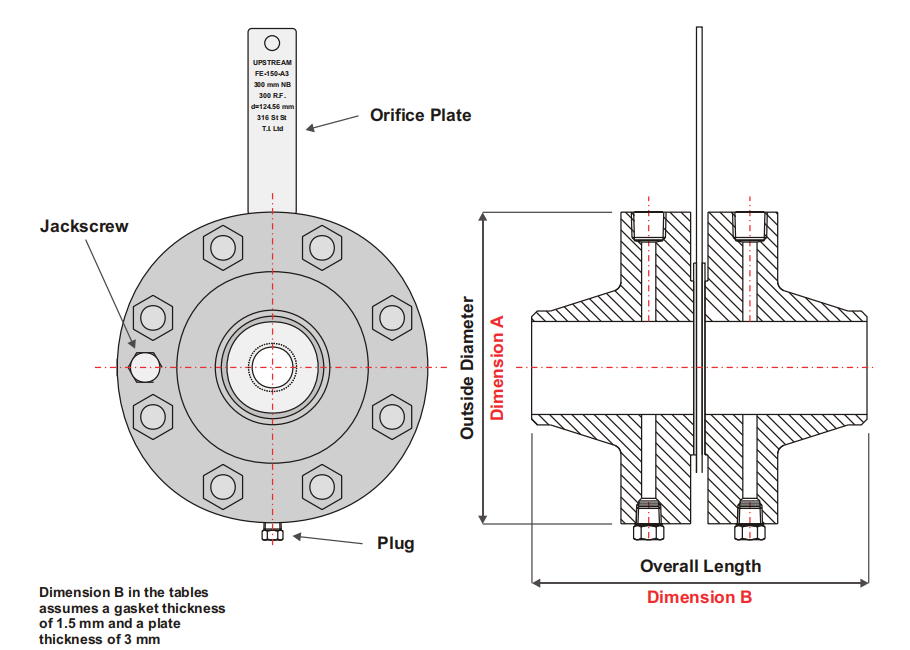

1. Uqwalaselo lweNtlako yeWeld

Uyilo lwehabhu olunwetshiweyo ukuze kusasazwe uxinzelelo olufanelekileyo

Utshintsho oluthambileyo ukusuka kwiflange ukuya kwipayipi kunciphisa ukuxinana

Ukuqina kwesakhiwo okuphuculweyo kwizicelo eziphantsi koxinzelelo oluphezulu

2. Inkqubo ye-Jack Screw edibeneyo

Ubuncinane izikrufu ze-jack ezimbini (ezingama-90° ukusuka komnye, ezinye izikrufu ziyafumaneka ngobukhulu obukhulu)

Imingxunya esemgangathweni ye-½"-13 ye-UNC enemisonto (ezinye iinkcukacha zemisonto ziyafumaneka)

Ilungiselela ukufakwa nokususwa kweepleyiti ze-orifice ezikhuselekileyo ngaphandle kokuqhaqha inkqubo

Ithintela ukonakala kobuso beflengi ngexesha lokugcinwa

3. Ukuchaneka kwe-Orifice Bore

Yenziwe ngomatshini ukuze ivumelane nobukhulu obungqongqo (± 0.001" umgangatho)

Ukugqitywa komphezulu webhore egudileyo (Ra ≤ 63 µin)

Ukugxila kugcinwe ngaphakathi kwe-0.005" TIR

4. Uyilo loBuso oluPhakanyisiweyo

Ubuso obuphakanyisiweyo obuyi-1/16" obuqhelekileyo (RF) obunesiphelo esirhabaxa (125-250 AARH)

Iintlobo zobuso ezizezinye ziyafumaneka (FF, RTJ, T&G)

Ukusebenza kakuhle kwe-gasket compression kunye nokutywina

UKUPHAKISHA NOKUPAKISHA

Ukupakisha okuKhuselekileyo

Ukusonga ngeplastiki nganye enokhuselo lwe-VCI

Iibhokisi zomthi ezinezibambiso ezifanelekileyo zokuthunyelwa kwamanye amazwe

Izigqubuthelo zokukhusela imisonto yesikrufu se-jack

Ukuchongwa okucacileyo kunye nokuphawulwa ngokweemfuno ze-ASME

Amaxwebhu okuthumela

Uluhlu lwe-invoyisi yorhwebo kunye noluhlu lokupakisha

Isatifikethi semvelaphi

Iphakheji yesatifikethi sezinto eziphathekayo

Iingxelo zovavanyo lweMill kunye nezatifikethi zokuhlolwa

UVAVANYO

1. Ukuqinisekiswa kwezinto

Uhlalutyo lweSpectrochemical

Uvavanyo lweempawu zoomatshini (ukuxinana, ukunyuka, ukunwebeka)

Uvavanyo lwempembelelo yeCharpy kwizicelo ezisebenzisa ubushushu obuphantsi

2. Uvavanyo olungatshabalalisiyo

Uvavanyo lokuNgena kolwelo (PT) ngokwe-ASME Sec V Inqaku 6

Uvavanyo lweMagnetic Particle (MT) lwezinto ze-ferritic

Uvavanyo lwe-Ultrasonic (UT) lweziphene zangaphakathi

Uvavanyo lokuqina kwiindawo ezibalulekileyo

3. Ukuqinisekiswa kobukhulu

Uvavanyo oluyi-100% ngokwe-ASME B16.36 nganye

Ukuqinisekiswa kobubanzi bebhore kunye nokuqina kwe-concentricity

Isangqa semingxunya yeBolt kunye nokuqinisekiswa kwepateni yokubhola

Ubungakanani kunye nokulinganiswa kobuso obuthe tyaba

ITYALA LENTSEBENZISWANO

I-Forged ASME B16.36 WN Orifice Flange eneJack Screw imele isiphelo sobunjineli be-metallurgical obuphambili, ukuveliswa ngokuchanekileyo, kunye noyilo olusebenzayo. Icandelo ngalinye lenziwe ngononophelo olungenamkhethe kwiinkcukacha, ukuqinisekisa ukusebenza okuthembekileyo kwiimeko zenkqubo ezinzima kakhulu. Ukuzibophelela kwethu kumgangatho, kunye namava eminyaka emininzi kushishino, kwenza ezi flanges zibe lukhetho olukhethwayo kwiinjineli kunye nabaqhubi kwihlabathi liphela abafuna ukuchaneka, ukuthembeka, kunye nokhuseleko kwiinkqubo zabo zokulinganisa ukuhamba kwamanzi.

INKQUBO YEMVELISO

| 1Khetha izinto zokwenyani ezikrwada | 2. Sika izinto ezikrwada | 3. Ukufudumeza kwangaphambili |

| 4. Ukubumba | 5. Unyango lobushushu | 6. Umatshini Onzima |

| 7. Ukubhola | 8. Ukuluka kakuhle | 9. Ukumakisha |

| 10. Uhlolo | 11. Ukupakisha | 12. Ukuhanjiswa |

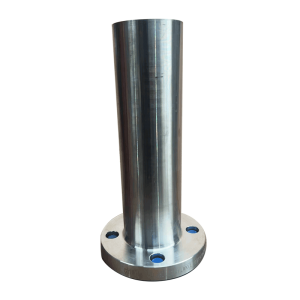

Sizisa iiflange zethu ze-orifice ezidityaniswe ngeempundu ezikumgangatho ophezulu, ezenzelwe ukuhlangabezana neemfuno ezifunekayo zezicelo ezahlukeneyo zoshishino. Iiflange zethu ze-orifice zenzelwe ukubonelela ngezisombululo ezithembekileyo nezisebenzayo zokulinganisa ukuhamba kolwelo, iigesi kunye nomphunga kwiipayipi.

Iiflange zethu ze-butt weld orifice zenziwe ngezinto ezikumgangatho ophezulu kwaye zinika ukuqina okugqwesileyo kunye nokumelana nokugqwala, okwenza zifaneleke ukusetyenziswa kwiindawo ezinzima nezingcolisayo. Ukulungiswa ngokuchanekileyo kweflange kuqinisekisa ukulingana okufanelekileyo kunye nokutywinwa okuqinileyo, kunciphisa umngcipheko wokuvuza kunye nokuqinisekisa ukusebenza kwexesha elide.

Uyilo lwentamo edibeneyo yeeflange zethu ze-orifice ludala unxibelelwano oluqinileyo nolukhuselekileyo kwinkqubo yepayipi ukuze kubekho uzinzo oluphuculweyo kunye nenkxaso. Olu yilo lukwanceda ekunciphiseni uxinzelelo kwiintambo zeflange, ngaloo ndlela luphucula ukuthembeka kwenkqubo iyonke.

Iiflange zethu ze-orifice ziyafumaneka ngobukhulu obahlukeneyo kunye novavanyo loxinzelelo ukuhlangabezana neemfuno ezahlukeneyo zesicelo. Nokuba zisetyenziswa kwimizi-mveliso yeoyile negesi, i-petrochemical, i-chemical processing okanye i-power generation, iiflange zethu ze-orifice ze-weld neck zibonelela ngomlinganiselo wokuhamba ohambelanayo nochanekileyo.

Ukongeza kulwakhiwo lwazo oluqinileyo, ii-orifice flanges zethu kulula ukuzifakela nokuzilungisa, nto leyo esindisa abathengi bethu ixesha elibalulekileyo kunye nezixhobo. Ukugqitywa komphezulu ogudileyo kunye nobukhulu obuchanekileyo kuphucula ngakumbi ukuphathwa nokuhlanganiswa.

Siyaqonda indima ebalulekileyo edlalwa ziiflange ze-orifice plate ekuqinisekiseni ukusebenza kakuhle nokhuseleko lweenkqubo zoshishino. Yiyo loo nto sizibophelele ekuboneleleni ngeemveliso ezihlangabezana nemigangatho ephezulu yomgangatho kunye neenkcukacha zokusebenza.

Ngee-flange zethu ze-butt weld orifice, ungathemba ukuba usetyenziso lwakho lokulinganisa ukuhamba kwamanzi luya kuxhamla ekusebenzeni okuthembekileyo, okuhlala ixesha elide nokuchanekileyo. Fumana umahluko ngee-flange zethu ze-butt weld orifice plate ezikumgangatho ophezulu kwaye wonyuse ukusebenza kakuhle kwemisebenzi yakho.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

I-Long Weld Neck Flange Uxinzelelo oluqhelekileyo lwe-LWN lwe...

-

I-Stainle ye-Orifice yoxinzelelo oluqhelekileyo ...

-

I-ANSI DIN eyenziwe ngeForged Class150 Stainless Steel Slip o ...

-

Umenzi okhethekileyo wokwakha uxinzelelo oluphezulu ...

-

I-DIN ANSI 150LB PN16 intsimbi engagqwaliyo 304 316 316...

-

Intsimbi Engagqwaliyo 304 304L 316 316L ASTM eyenziwe ngomkhonto...