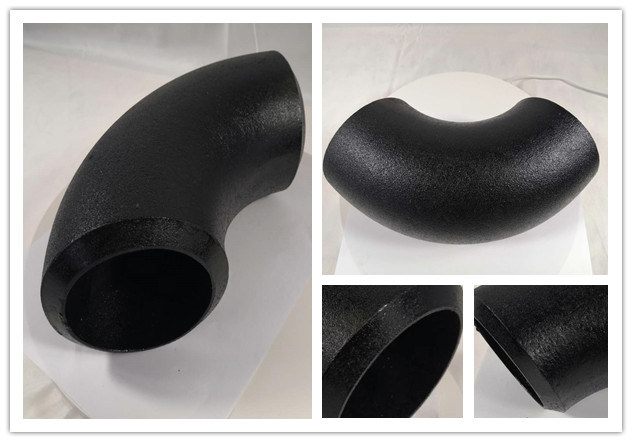

Ukufakelwa kombhobho wengqiniba we-DN25 25A sch160 we-90 degree

I-Factory DN25 SCH160 90-Degree Elbow yi-fitting yepayipi enoxinzelelo oluphezulu eyenziwe ngokuchanekileyo, eyenzelwe ukusetyenziswa okubalulekileyo apho ukuthembeka kunye nokuqina kwesakhiwo kungaxoxiswana ngako. Yenziwe ngentsimbi yekhabhoni engenamthungo ye-ASTM A234 WPB ehambelana ngokupheleleyo nemigangatho ye-ASME B16.9, le ngqiniba ye-1.5D Long Radius sisisombululo esifanelekileyo sokudibanisa kwiinkqubo zepayipi ezinoxinzelelo oluphezulu zeShedyuli 160. Ukwakhiwa kwayo okungenamthungo kuqinisekisa ukuxinana koxinzelelo okuphezulu, ukumelana nokudinwa okugqwesileyo, kunye nokhuseleko oluphuculweyo xa kuthelekiswa nezixhobo ezidityanisiweyo, okwenza ukuba ibe yinxalenye ekhethwayo yeenkonzo ezifuna kakhulu kwiziseko ze-petrochemical, ukuveliswa kwamandla, kunye neoyile negesi.

Le ngqiniba yenzelwe ukuba kube lula ukutshintsha okuthe tye kwe-90-degree kwicala lokuhamba kolwelo olunoxinzelelo oluphezulu, ukunciphisa ukuxinana kunye nokuhla koxinzelelo olucwangcisiweyo ngenxa yerediyasi yayo egobileyo ye-1.5D. Iinkcukacha zezinto ze-ASTM A234 WPB ziqinisekisa ukudityaniswa okugqwesileyo kunye neempawu zoomatshini eziqinileyo, okuvumela ukudalwa kwamalungu aqinileyo, angenamanzi avuzayo ayinxalenye ebalulekileyo yombhobho. Yenzelwe ukuhlala ixesha elide kunye nokusebenza okungagungqiyo kwiindawo zokusebenza ezinzima, olu lungelelwaniso lusisiseko sokwakha iinjineli kunye nabakhi kwihlabathi liphela abazimisele ukwakha iinethiwekhi zepayipi eziqinileyo nezisemgangathweni ophezulu.

IIPARAMETHA ZEMVELISO

| Igama lemveliso | Ingqiniba yombhobho |

| Ubungakanani | Ingqiniba engenamthungo eyi-1/2"-36" (ingqiniba ye-SMLS), i-26"-110" idityaniswe ngomthungo. Ububanzi obukhulu bangaphandle bunokuba yi-4000mm |

| Umgangatho | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njl. |

| Ubukhulu bodonga | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS njl. |

| Isidanga | 30° 45° 60° 90° 180°, njl. |

| Irediyasi | Irediyasi ye-LR/ende/R=1.5D,SR/Irediyasi emfutshane/R=1D |

| Isiphelo | Isiphelo seBevel/BE/buttweld |

| Umphezulu | umbala wendalo, ivarnish, upende omnyama, ioyile yokulwa nomhlwa njl. |

| Izinto eziphathekayo | Intsimbi yekhabhoni:A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njl. |

| Intsimbi yombhobho:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njl. | |

| Intsimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza, umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

IZIXHOBO ZEMIPAYIPI

Izixhobo zombhobho ezidityanisiweyo ngeempundu ziquka ingqiniba yombhobho wentsimbi, i-tee yombhobho wentsimbi, i-steel pipe reduer, i-steel pipe cap. Zonke ezo zixhobo zombhobho zokudityaniselwa ngeempundu, singazibonelela kunye, sinamava emveliso angaphezulu kweminyaka engama-20.

Ukuba unomdla nakwezinye izixhobo, nceda ucofe ku-LINK elandelwayo ukuze ujonge iinkcukacha.

I-PIPE TEE ISINCIPHI SOKUNCIPHISA IMIBHAWU Isiciko sepayipi I-PIPE BEND IZIXHOBO EZIQINISEKISIWEYO

Izinto kunye noMveliso:

Le ngqiniba yenziwe ngepayipi engenamthungo ye-ASTM A234 WPB, into eyenziwe ngentsimbi yekhabhoni etyunjiweyo echazwe kwinkonzo yobushushu obuphakathi, enika ibhalansi efanelekileyo yamandla kunye nokuqina. Imveliso isebenzisa inkqubo yokutyhala eshushu engenamthungo okanye yokufudumeza kunye nokugoba. Le ndlela iqinisekisa ukuba umzimba wengqiniba awunayo nayiphi na ingqiniba ye-weld ende, ngaloo ndlela isusa umgca onokubakho wobuthathaka. Emva kokwenziwa, ukufakwa ngakunye kwenziwa unyango lobushushu oluqhelekileyo ukuze kuphuculwe isakhiwo sengqolowa, kuncitshiswe uxinzelelo lokwakheka, kwaye kubuyiselwe iimpawu ezifanelekileyo zoomatshini zesixhobo.

Ulawulo oluchanekileyo lwemilinganiselo:

Yenziwe ngokubambelela ngokungqongqo kwimilinganiselo yokunyamezelana ye-ASME B16.9.

- Ububanzi bangaphandle: 33.4 mm (± 0.8mm ukunyamezelana).

- Ubukhulu Bodonga: Buhambelana nobukhulu bodonga obuncinci be-SCH160 (malunga ne-6.55mm). Imveliso iqinisekisa ubukhulu bodonga obufanayo, kunye nokuncitshiswa kwezinto ezingaphandle ezilawulwa ngononophelo ngaphakathi kwemida evumelekileyo ye-ASME.

- Ubukhulu obuphakathi ukuya ekupheleni: Igcinwe ngokuchanekileyo kwi-38mm (± 1.5mm).

- Ukungajikelezi: Ilawulwa ngokuqinileyo eziphelweni zepayipi ukuqinisekisa ukulungelelaniswa ngokugqibeleleyo kunye nokuhambelana nombhobho wokutshatisa.

- I-Weld Bevel: Zombini iziphelo zine-weld bevel eyenziwe ngomatshini engama-37.5° enomhlaba oyi-1.6mm (± 0.8mm), ebonelela ngolungiselelo olucocekileyo noluhambelanayo lokuwelda okusemgangathweni ophezulu.

Umphezulu kunye nokuMakisha:

Imiphezulu yangaphakathi neyangaphandle igudile, ikhuthaza indlela yokuhamba engaphazanyiswayo ukunciphisa ukulahleka koxinzelelo. Ngokwesiqhelo, umphezulu unikezelwa ngokugqitywa kwesikali se-black mill; ukuqhumisa isanti ukuya kucoceko lwe-Sa2.5 kuyafumaneka xa kuceliwe. Ingqiniba nganye iphawulwa ngokusisigxina ngokuhambelana ne-ASTM A960, kubandakanya: Udidi lwezinto (A234 WPB), Ubungakanani (1" SCH160), Ukuchongwa koMvelisi okanye uphawu, kunye neNombolo yoBushushu elandelekayo.

Ukuqinisekiswa kwezinto eziluhlaza:

Yonke ibhetshi yombhobho ongenamthungo we-ASTM A234 WPB esetyenziswa kwimveliso ihamba neSatifikethi soVavanyo lweMill esihambelana ne-ASTM A960. Emva kokufumana, senza uhlalutyo lwe-spectrochemical ukuqinisekisa ukuthotyelwa kweemfuno zomgangatho wekhemikhali kwizinto ezifana neCarbon, iManganese, iSilicon, iPhosphorus, kunye neSulfur. Iisampulu ezivela kwindawo efanayo yobushushu ziyavavanywa ukuze kuqinisekiswe amandla okutsalwa, amandla okutsalwa, kunye nobude obuhlangabezana neemfuno ze-A234 WPB (umz., amandla okutsalwa angama-415 MPa, amandla okutsalwa angama-240 MPa).

Uhlolo lweMilinganiselo kunye neJiyomethri:

Ingqiniba nganye egqityiweyo ihlolwa ngokupheleleyo.

- Ii-Digital Calipers kunye ne-Ultrasonic Thickness Gauges zisetyenziselwa ukulinganisa ngokuchanekileyo ububanzi bangaphandle kunye nobukhulu bodonga kwiindawo ezininzi, kugxilwe kakhulu kwi-extrados (i-outer bend) apho kunokwenzeka khona ukuncitshiswa.

- Iiprotractor kunye neeGauges eziphakathi nendawo ziqinisekisa i-engile yokugoba engama-90 degrees kunye nomgama ophakathi nendawo ukuya ekupheleni.

- Iigeyiji ezingaphandle kokujikeleza zijonga ukuba i-port ellipticity ingakanani na.

- Iigeyiji zeWeld Bevel ziqinisekisa ukuba i-engile yebevel kunye nobukhulu bomhlaba buhambelana neenkcukacha zewelding.

Uvavanyo Lomphezulu Nolungatshabalalisiyo (NDT):

- Ukuhlolwa Okubonakalayo: Ukuhlolwa ngokucokisekileyo kwemiphezulu yangaphakathi nangaphandle ukuze kubonwe iziphene ezinje ngeentanda, imithungo, okanye ii-laminations.

- Uvavanyo lweMagnetic Particle (MT) okanye uVavanyo lweLiquid Penetrant (PT): Lonke umphezulu wangaphandle, kuquka neziphelo ezibengezelayo, uhlolwa kusetyenziswa ezi ndlela ukuze kufunyanwe iziphene zomphezulu kunye nomgangatho okufutshane. Olu vavanyo lwenziwa ngabasebenzi abaqinisekisiweyo kwi-ASNT SNT-TC-1A Level II.

- Ukuskena kwe-Ultrasonic Thickness (UT): Ukuskena okujolisiweyo kwenziwa kwiindawo ezingaphandle nakwezinye iindawo ezinokuncitshiswa ukuqinisekisa ukuba ubukhulu bodonga buhlangana okanye budlula ubuncinane boyilo.

Ulawulo lweNkqubo kunye noQinisekiso:

- Ukujongwa koNyango loBushushu: Ubushushu kunye nexesha lonyango lobushushu oluqhelekileyo zirekhodwa ngokuzenzekelayo kwaye zigcinwe, ukuqinisekisa ukuhambelana kwenkqubo kunye nokulandeleka kwayo.

- Uvavanyo lweHydrostatic (Ukhetho): Xa umthengi ecela, iingqiniba zomntu ngamnye zinokuvavanywa ngoxinzelelo lwehydrostatic, ngesiqhelo nge-1.5 yereyithingi yoxinzelelo kubushushu obufanelekileyo, ukuqinisekisa ukuthembeka okuqulathe uxinzelelo kunye nokuqina kokuvuza.

Uhlolo lokugqibela kunye namaxwebhu:

Yonke idatha yokuhlolwa irekhodwa kwiSicwangciso soHlolo noVavanyo (i-ITP). Iimveliso ezidlula kuzo zonke iitshekhi zifumana iSatifikethi sokuKhululwa koHlolo lokugqibela. Iphakheji epheleleyo yamaxwebhu ekhoyo ibandakanya: iSatifikethi soVavanyo lweMill (i-MTC 3.1), iNgxelo yoVavanyo oluneMilinganiselo, iiNgxelo zoVavanyo olungonakalisiyo (ukuba lukhona), iiRekhodi zoNyango loBushushu, kunye neeNgxelo zoVavanyo loMntu wesithathu (xa ziceliwe ngumthengi).

UMPHEZULU WE-ELBOW

Ukuqhuma kweSand

Emva kokwenza ubushushu, silungiselela ukuqhuma kwesanti ukuze umphezulu ucoceke kwaye uthambe.

Emva kokuqhuma kweSand, ukuze kuthintelwe ukugqwala, kufuneka upeyinte ngomnyama okanye ngeoyile yokulwa nomhlwa, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, umphezulu onyamaleleyo, njl. Oko kuxhomekeke kwisicelo somthengi.

UNYANGO LOBUSHUSHU

1. Gcina isampuli yezinto ezikrwada ukuze zilandelelwe.

2. Lungiselela unyango lobushushu ngokwemigangatho emiselweyo.

UKUPHAWULA

Imisebenzi eyahlukeneyo yokumakisha, inokugoba, ipeyintwe, ibhalwe ilebhile. Okanye xa ucela. Siyamkela ukumaka iLOGO yakho.

IIFOWUNI EZINIKA INKCAZELO

1. Isiphelo se-Bevel ngokwe-ANSI B16.25.

2. Ukuqala ngokuqhumisa isanti, uze emva koko upeyinte kakuhle. Ingafakwa ivarnish.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Ngaphandle kokulungiswa kwe-weld.

UVAVANYO

1. Ubungakanani bokulinganisa, konke kuxhomekeke ekunyamezeleni okuqhelekileyo.

2. Ukunyamezelana kobukhulu: +/- 12.5%, okanye ngokwesicelo sakho

3. I-PMI

4. Uvavanyo lwe-MT, UT, X-ray

5. Yamkela uhlolo lomntu wesithathu

6. Nikeza isiqinisekiso se-MTC, EN10204 3.1/3.2

UKUPAKISHA NOKUTHUMELA

Emva kokuvunywa kokugqibela, ingqiniba nganye ye-DN25 SCH160 igqunywa ngoko nangoko ngeoyile yokulwa nokubola kwiziphelo ezibekiweyo kunye neendawo ezenziwe ngomatshini. Emva koko ivalwa nganye nganye kwingxowa yeplastiki yeVapor Corrosion Inhibitor (VCI), inika ukhuseleko oluqinileyo ekuboleni ngexesha lokuhamba nokugcinwa. Kwiiodolo ezinkulu, iingqiniba ezipakishwe nganye nganye zicwangciswe kakuhle kwiikreyithi zokhuni eziqinileyo zokuthumela ngaphandle okanye kwiibhokisi eziqinisiweyo, kunye nezahluli zefoam okanye zekhadibhodi zangaphakathi ukuthintela umonakalo wokudibana. Iikreyithi ziqiniswa ngaphandle ngeentambo zentsimbi kwaye ziphawulwe ngokucacileyo ngeempawu zokuphatha ezifana ne "Fragile" kunye ne "Keep Dry."

Izicelo Ezininzi Zemizi-mveliso:

Le ngqiniba enoxinzelelo oluphezulu, eludongeni olunzima yeyona ndlela ifanelekileyo kwizicelo ezibalulekileyo kumashishini aphambili:

- Ioyile neGesi: Imigca yoxinzelelo oluphezulu kwiindawo zokuhlanganisa iingcambu zemithombo, ii-metering skids, iipayipi zesitishi se-compressor, kunye neeyunithi zokucoca ngamanzi ezinoxinzelelo oluphezulu kwiindawo zokucoca.

- Ukuveliswa koMbane: Imigca yamanzi okuhambisa amanzi anoxinzelelo oluphezulu, iinkqubo eziphambili zokudlula umphunga, kunye noqhagamshelo lwezifudumezi ezinoxinzelelo oluphezulu kwizityalo zamandla.

- Iikhemikhali kunye neekhemikhali zePetrochemical: Imigca yokutya kunye nokukhupha ii-reactors ezinoxinzelelo oluphezulu, uqhagamshelo lwe-high-pressure heat exchangers, kunye nemibhobho kwiinkqubo zokwenziwa koxinzelelo oluphezulu (umz., urea).

- Oomatshini Boshishino: Imibhobho yokungena kunye neyokuphuma yeepompo zoxinzelelo oluphezulu, imigca yenkqubo ye-hydraulic, kunye nokusetyenziswa okuxhomekeke ekujikelezeni koxinzelelo olukhulu okanye ekubetheni ngamandla.

Iingenelo zethu zoKhuphiswano:

- Ingcali kwiZixhobo zoXinzelelo oluPhezulu: Sinobuchule obukhethekileyo ekuveliseni i-SCH160 kunye nezixhobo zodidi oluphezulu, kunye nokukhethwa kwezinto kunye nolawulo lwenkqubo olulungiselelwe ngokukodwa inkonzo yoxinzelelo oluphezulu.

- Isiqinisekiso Sobunyulu Esingenamthungo: Ukuzibophelela kwethu kubuchwepheshe bokuvelisa obungenamthungo kususa iingozi ezinxulumene nemithungo yokuwelda, nto leyo enika ukhuseleko nokuthembeka okuphezulu kubathengi bethu.

- Ulawulo Oluqinileyo Lomgangatho: Inkqubo yokuhlola enamanqanaba amaninzi, enokuhlolwa okungqongqo kwinqanaba ngalinye lemveliso—ingakumbi i-NDT ebalulekileyo kwizinto ezinoxinzelelo oluphezulu—iqinisekisa ifilosofi engenasiphako kwiimveliso eziphumayo.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

I-Lap joint 321ss i-flange yentsimbi engenamthungo ...

-

I-ANSI B16.9 Carbon Steel Bend ene-degree ezingama-45 yokuWelda

-

I-ASTM B 16.9 Pipe Fitting Carbon Steel Butt Weld ...

-

I-ANSI B16.9 intsimbi engatyiwayo ene-butt weld ye-45 degree ...

-

Izixhobo zePipe zeStainless Steel White Forge ...

-

Intsimbi engenasici 45/60/90/180 Degree Elbow