IIPARAMETHA ZEMVELISO

| Igama lemveliso | Ingqiniba yombhobho |

| Ubungakanani | I-1/2"-36" engenamthungo, i-6"-110" edityaniswe ngomthungo |

| Umgangatho | I-ANSI B16.9, EN10253-4, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, engekho semgangathweni, njl. |

| Ubukhulu bodonga | I-SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, eyenziwe ngokwezifiso kwaye njl. |

| Isidanga | 30° 45° 60° 90° 180°, eyenziwe ngokwezifiso, njl. |

| Irediyasi | I-LR/i-radius ende/R=1.5D, i-SR/i-radius emfutshane/R=1D okanye eyenziwe ngokwezifiso |

| Isiphelo | Isiphelo seBevel/BE/buttweld |

| Umphezulu | i-pickled, i-sand rolling, i-polished, i-mirror polishing njalo njalo. |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo njalo njalo. |

| Intsimbi engagqwaliyo ephindwe kabini:I-UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 njl. | |

| I-alloy ye-nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, iMonel400, iAlloy20 njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza, umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

I-ELBOW YESIBHAKABHAKA SENTSIMBI EMHLOPHE

Ingqiniba yentsimbi emhlophe ibandakanya ingqiniba yentsimbi engagqwaliyo (ingqiniba yentsimbi), ingqiniba yentsimbi engagqwaliyo ene-super duplex kunye nengqiniba yentsimbi ye-nickel alloy.

UHLOBO LWESIBANDLA

Ingqiniba inokuba phakathi kwe-engile yecala, iintlobo zoqhagamshelo, ubude kunye ne-radius, iintlobo zezinto, ingqiniba elinganayo okanye ingqiniba yokunciphisa.

45/60/90/180 Degree Elbow

Njengoko sisazi, ngokwendlela oluhamba ngayo ulwelo lwemibhobho, ingqiniba inokwahlulwa ibe ziidigri ezahlukeneyo, ezifana needigri ezingama-45, iidigri ezingama-90, iidigri ezili-180, ezizezona ziqhelekileyo. Kwakhona kukho iidigri ezingama-60 kunye needigri ezili-120, kwezinye iipayipi ezikhethekileyo.

Yintoni i-Elbow Radius

Irediyasi yengqiniba ithetha irediyasi egobileyo. Ukuba irediyasi ifana nobubanzi bombhobho, ibizwa ngokuba yi-short radius elbow, ekwabizwa ngokuba yi-SR elbow, ngokuqhelekileyo kwiipayipi eziphantsi koxinzelelo kunye nesantya esiphantsi.

Ukuba i-radius inkulu kunobubanzi bombhobho, i-R ≥ 1.5 Diameter, ngoko siyibiza ngokuba yi-long radius elbow (LR Elbow), esetyenziselwa imibhobho yoxinzelelo oluphezulu kunye nesantya sokuhamba kwamanzi esiphezulu.

Uhlulo ngokwezinto eziphathekayo

Masizazise ezinye zezinto ezikhuphisanayo esizibonelelayo apha:

Ingqiniba yentsimbi engatyiwayo: Ingqiniba yeSus 304 sch10,Ingqiniba ende ye-316L 304 ene-90 degrees, ingqiniba emfutshane ye-904L

Ingqiniba yentsimbi ye-alloy: I-Hastelloy C 276 Elbow, ingqiniba emfutshane ye-alloy engama-20

Ingqiniba yentsimbi ye-Super duplex: I-Uns31803 Duplex Stainless Steel 180 Degree Elbow

IIFOWUNI EZINIKA INKCAZELO

1. Isiphelo se-Bevel ngokwe-ANSI B16.25.

2. Ipolishi erhabaxa kuqala ngaphambi kokuba iqengqeleke isanti, emva koko umphezulu uya kuba mpuluswa kakhulu.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Ngaphandle kokulungiswa kwe-weld.

5. Ukulungiswa komphezulu kunokucolwa, ukuqengqeleka kwesanti, ukugqitywa kwe-matt, ukupolishwa kwesipili. Ngokuqinisekileyo, ixabiso lahlukile. Ngokwesalathiso sakho, umphezulu wokuqengqeleka kwesanti ngowona udumileyo. Ixabiso le-sand roll lifanelekile kubathengi abaninzi.

UVAVANYO

1. Ubungakanani bokulinganisa, konke kuxhomekeke ekunyamezeleni okuqhelekileyo.

2. Ukunyamezelana kobukhulu: +/-12.5%, okanye ngokwesicelo sakho.

3. I-PMI

4. Uvavanyo lwe-PT, UT, X-ray

5. Yamkela uhlolo lomntu wesithathu.

6. Nikeza i-MTC, isiqinisekiso se-EN10204 3.1/3.2, i-NACE.

7. I-ASTM A262 yokuziqhelanisa E

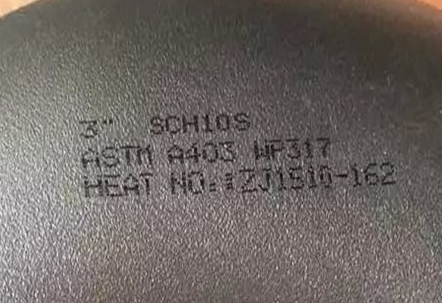

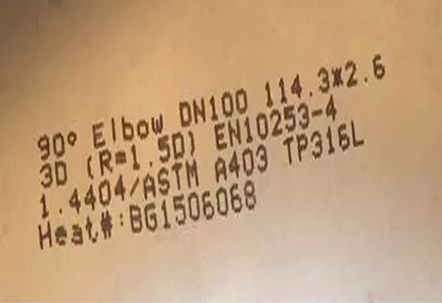

UKUPHAWULA

Imisebenzi eyahlukeneyo yokumakisha ingabakho xa ucela. Siyayamkela i-LOGO yakho.

UKUPAKISHA NOKUTHUMELA

1. Ipakishwe ngebhokisi yeplywood okanye ipallet yeplywood ngokwe-ISPM15.

2. siza kubeka uluhlu lokupakisha kwiphakheji nganye.

3. Siza kubeka iimpawu zokuthumela kwiphakheji nganye. Amagama eempawu akwisicelo sakho.

4. Zonke izinto zokupakisha iinkuni azinazo izifunxi.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

I-ANSI B16.9 intsimbi engatyiwayo ene-butt weld ye-45 degree ...

-

I-intshi ezi-8 zentsimbi engagqwaliyo isiciko sombhobho wokuphela kwesiciko ...

-

sch80 ss316 intsimbi engagqwaliyo Butt Weld Eccentri ...

-

Ishedyuli ye-ANSI b16.9 intshi ezingama-36 40 Butt Weld carbon...

-

Intsimbi ye-DN500 intshi ezingama-20 ye-Alloy A234 WP22 engenamthungo 90...

-

Intsimbi engatyiwayo ende i-bend1d 1.5d 3d 5d radius 3...