Intsimbi yeCarbon engaphantsi kobushushu obuphantsi Iingqengqelo ezingenamthungo

Zenzelwe inkonzo ebalulekileyo kwiindawo ezishushu kakhulu nezinobushushu obuphantsi, ii-Carbon Steel Low-Temperature Seamless Elbows zethu zenziwe ngezinto ezikumgangatho ophezulu ezifana ne-API 5L X65 okanye intsimbi ekhethekileyo ye-ASTM A333 Grade 6. Zifumaneka kuzo zombini ii-configurations ze-90° kunye ne-180° ezine-standard 1.5D Long Radius, ezi ngqiniba ze-butt weld zenzelwe ukugcina ukuqina okugqwesileyo kunye nokuqina kwesakhiwo phantsi kweemeko ezingaphantsi kwe-zero, ukuthintela ukwaphuka okubuthathaka kwizicelo ezifana nokucubungula i-LNG, ukugcinwa kwe-cryogenic, kunye neenkqubo zepayipi ze-arctic.

Zenziwe ngenkqubo yokwenza ubushushu engenamthungo, ezi ngqiniba zibonelela ngokuqhubekeka okuphezulu kwe-metallurgical kunye nokuthembeka koxinzelelo xa kuthelekiswa nezinye ezidityanisiweyo. I-radius yokugoba ye-1.5D iqinisekisa ukuhamba kakuhle kunye nokuxinana okuncinci kunye nokwehla koxinzelelo, ngelixa ukulungiswa kwe-weld bevel echanekileyo kuqinisekisa ukujija kwentsimi esemgangathweni ophezulu, egcweleyo. Ezi zixhobo zikhetho oluthembekileyo lweenjineli eziyila iinkqubo zepayipi ezikhuselekileyo nezihlala ixesha elide ekufuneka zisebenze ngokuthembekileyo ukusuka kwindawo engqongileyo ukuya kumaqondo obushushu abandayo.

IIPARAMETHA ZEMVELISO

| Igama lemveliso | Ingqiniba yombhobho |

| Ubungakanani | Ingqiniba engenamthungo eyi-1/2"-36" (ingqiniba ye-SMLS), i-26"-110" idityaniswe ngomthungo. Ububanzi obukhulu bangaphandle bunokuba yi-4000mm |

| Umgangatho | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njl. |

| Ubukhulu bodonga | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS njl. |

| Isidanga | 30° 45° 60° 90° 180°, njl. |

| Irediyasi | Irediyasi ye-LR/ende/R=1.5D,SR/Irediyasi emfutshane/R=1D |

| Isiphelo | Isiphelo seBevel/BE/buttweld |

| Umphezulu | umbala wendalo, ivarnish, upende omnyama, ioyile yokulwa nomhlwa njl. |

| Izinto eziphathekayo | Intsimbi yekhabhoni:A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njl. |

| Intsimbi yombhobho:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njl. | |

| Intsimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza, umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

IZIXHOBO ZEMIPAYIPI

Izixhobo zombhobho ezidityanisiweyo ngeempundu ziquka ingqiniba yombhobho wentsimbi, i-tee yombhobho wentsimbi, i-steel pipe reduer, i-steel pipe cap. Zonke ezo zixhobo zombhobho zokudityaniselwa ngeempundu, singazibonelela kunye, sinamava emveliso angaphezulu kweminyaka engama-20.

Ukuba unomdla nakwezinye izixhobo, nceda ucofe ku-LINK elandelwayo ukuze ujonge iinkcukacha.

I-PIPE TEE ISINCIPHI SOKUNCIPHISA IMIBHAWU Isiciko sepayipi I-PIPE BEND IZIXHOBO EZIQINISEKISIWEYO

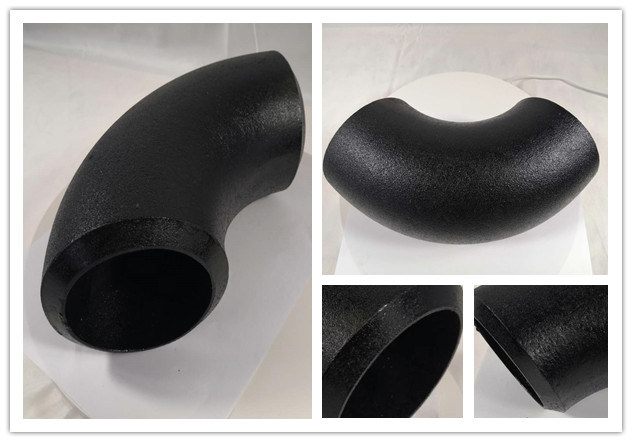

I-BUTT WLDED PIPE ELBOW

Ingqiniba yentsimbi yinxenye ebalulekileyo kwinkqubo yemibhobho yokutshintsha indlela ukuhamba kolwelo. Isetyenziselwa ukudibanisa imibhobho emibini enobubanzi obufanayo okanye obahlukeneyo, nokwenza umbhobho ujike uye kwicala elithile le-45 degrees okanye i-90 degrees.

Kwi-industrial pipe elbow, uhlobo lwe-connectin end yi-butt weld, ngokwe-ANSI B16.25. I-butt weld ingachazwa njenge-butt welding, i-buttweld, kunye ne-bevel end. BW

UHLOBO LWESIBANDLA

Ingqiniba inokubalwa ukusuka kwikona yecala, iintlobo zoqhagamshelo, ubude kunye nerediyasi, kunye neentlobo zezinto.

Ihlelwe ngokwe-Direction Angle

Njengoko sisazi, ngokwendlela oluhamba ngayo ulwelo lwemibhobho, ingqiniba inokwahlulwa ibe ziidigri ezahlukeneyo, ezifana needigri ezingama-45, iidigri ezingama-90, iidigri ezili-180, ezizezona ziqhelekileyo. Kwakhona kukho iidigri ezingama-60 kunye needigri ezili-120, kwezinye iipayipi ezikhethekileyo.

Kwingqiniba yeedigri ezingama-90, kuchazwe nengqiniba yeedigri ezingama-90, okanye ingqiniba yeedigri ezingama-90.

Yintoni i-Elbow Radius

Irediyasi yengqiniba ithetha irediyasi egobileyo. Ukuba irediyasi ifana nobubanzi bombhobho, ibizwa ngokuba yi-short radius elbow, ekwabizwa ngokuba yi-SR elbow, ngokuqhelekileyo kwiipayipi eziphantsi koxinzelelo kunye nesantya esiphantsi.

Ukuba i-radius inkulu kunobubanzi bombhobho, i-R ≥ 1.5 Diameter, ngoko siyibiza ngokuba yi-long radius elbow (LR Elbow), esetyenziselwa imibhobho yoxinzelelo oluphezulu kunye nesantya sokuhamba kwamanzi esiphezulu.

Ukuba i-radius ingaphezulu kwe-1.5D, soloko ibizwa ngokuba yi-bend. I-elbow bend pipe fittings. Ezifana ne-2d elbow, i-2d bend, i-3d elbow, i-3d bend, njl.

Uhlulo ngokwezinto eziphathekayo

Intsimbi yekhabhoni, ekwabizwa ngokuba yintsimbi ethambileyo okanye intsimbi emnyama. Njenge-ASTM A234 WPB

Ukuba ufuna iingqiniba zentsimbi engagqwaliyo, nceda ucofe eli khonkco ukuze ufumane iinkcukacha ezithe vetshe:IINGQONDO ZENTSIMBI ENGAGQIBI

Uhlobo lweMilo

Ingaba yingqiniba elinganayo okanye Ukunciphisa ingqiniba

UMPHEZULU WE-ELBOW

Ukuqhuma kweSand

Emva kokwenza ubushushu, silungiselela ukuqhuma kwesanti ukuze umphezulu ucoceke kwaye uthambe.

Emva kokuqhuma kweSand, ukuze kuthintelwe ukugqwala, kufuneka upeyinte ngomnyama okanye ngeoyile yokulwa nomhlwa, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, umphezulu onyamaleleyo, njl. Oko kuxhomekeke kwisicelo somthengi.

Izinto kunye neMetallurgy:

Iingqiniba zenziwe ngepayipi engenamthungo eqinisekisiweyo kwi-API 5L X65 ukuze zisetyenziswe ngamandla aphezulu okanye kwi-ASTM A333 Grade 6 ukuze zifumane iimpawu eziqinisekisiweyo zokuchaphazela ubushushu obuphantsi. Ezi ntsimbi zicociwe kakuhle, zifile ngokupheleleyo, kwaye zihlala zilungelelaniswa ukuze kufezekiswe amaxabiso afunekayo e-Charpy V-Notch (CVN) impembelelo kubushushu obuncinci obuchaziweyo. Ikhemistri ilawulwa ukunciphisa izinto ezikhuthaza ukuqhekeka, ukuqinisekisa ukuqina okugqwesileyo kokuqhekeka kwiindawo ezibandayo.

Inkqubo Yokuvelisa Engenamthungo:

Iingqiniba zenziwa ngokusebenzisa ukugoba okushushu okulawulwayo kombhobho ongenamthungo okanye inkqubo yokutyhala eshushu. Zombini ezi ndlela zigcina ukulingana kwezinto ngaphandle kokudala umthungo othe tyaba. Emva kokwakheka, iingqiniba zifumana unyango lobushushu oluqhelekileyo ukuze kuphuculwe isakhiwo sengqolowa, kuncitshiswe uxinzelelo, kwaye kubuyiselwe iimpawu zoomatshini ezibalulekileyo ekusebenzeni kobushushu obuphantsi.

Ubunjineli obuchanekileyo kunye nobukhulu:

Yenziwe ngokungqongqo ngokwemilinganiselo ye-ASME B16.9.

Ubukhulu obuvela embindini ukuya ekupheleni/phakathi ukuya embindini: Ilawulwa ngokuchanekileyo ukuze kube noyilo oluchanekileyo lwemibhobho.

Ulawulo loBungqingqwa boDonga: Le nkqubo iqinisekisa ubungqingqwa obufanayo. Ingqwalasela ekhethekileyo inikwa kwi-extrados (igophe langaphandle) ukuze kugcinwe ukuncitshiswa ngaphakathi kwemida evumelekileyo ye-ASME B16.9 (ngesiqhelo i-12.5%).

Ukungabi nasiphako kunye neBevel: Iziphelo zenziwe ngomatshini ukuqinisekisa ukuba zijikelezile ukuze zilingane kakuhle. Ibevel yokuwelda ye-37.5° ehambelanayo enomhlaba we-1.6mm ilungiselelwe kuzo zombini iziphelo.

Ukumakisha kunye nokulandeleka:

Ingqiniba nganye igximfizwa ngokusisigxina ngokwe-ASTM A960, kuquka: Iinkcukacha zezinto (umz., i-API 5L X65 okanye i-A333 Gr.6), Inombolo yobushushu, ubungakanani, ishedyuli yodonga, isazisi somenzi, kunye nesichazi-magama "se-LT" (ubushushu obuphantsi). Oku kuqinisekisa ukulandeleka ngokupheleleyo ukusuka kwindawo yokugaya intsimbi ukuya kwimveliso egqityiweyo.

UNYANGO LOBUSHUSHU

1. Gcina isampuli yezinto ezikrwada ukuze zilandelelwe.

2. Lungiselela unyango lobushushu ngokwemigangatho emiselweyo.

UKUPHAWULA

Imisebenzi eyahlukeneyo yokumakisha, inokugoba, ipeyintwe, ibhalwe ilebhile. Okanye xa ucela. Siyamkela ukumaka iLOGO yakho.

IIFOWUNI EZINIKA INKCAZELO

1. Isiphelo se-Bevel ngokwe-ANSI B16.25.

2. Ukuqala ngokuqhumisa isanti, uze emva koko upeyinte kakuhle. Ingafakwa ivarnish.

3. Ngaphandle kwe-lamination kunye neentanda.

4. Ngaphandle kokulungiswa kwe-weld.

UVAVANYO

Ubushushu ngabunye bentsimbi bunikwa iSatifikethi soVavanyo lweMill esipheleleyo (MTC 3.2) esichaza ikhemistri kunye neempawu zoomatshini. Senza uVavanyo lweMpahla oluQinisekileyo (PMI) kunye nokuhlolwa kobukhulu be-ultrasonic kumbhobho oluhlaza. Uqinisekiso oluphambili yiCharpy V-Notch Impact Testing ngokwe-ASTM A370. Iiseti zeesampuli ezintathu zivavanywa kubushushu obuncinci boyilo (umz., -46°C) ukuqinisekisa ukuba amandla afunxwayo ayahlangabezana okanye adlula iimfuno ezichaziweyo (umz., ≥ 20J okanye 27J ngokwe-ASTM A333).

UKUPAKISHA NOKUTHUMELA

Ukuthintela ukugqwala ngexesha lokuhamba, iziphelo ezijijekileyo kunye neendawo eziveziweyo zigqunywa ngesixhobo sokuthintela ukugqwala sexesha elifutshane nesisuswa lula. Ingqiniba nganye emva koko isongelwe ngefilimu ye-VCI (Vapor Corrosion Inhibitor) okanye iplastiki enzima. Kwiingqiniba ezinzima okanye ezinkulu, ii-cradles zomthi okanye iikreyithi ezenziwe ngokwezifiso zisetyenziselwa ukubonelela ngenkxaso yesakhiwo kunye nokuthintela ukuguguleka.

Sisebenzisa iindlela ezahlukeneyo ngokusekelwe kubungakanani beodolo kunye nokungxamiseka: ukuthunyelwa ngenqwelo moya kwezinto ezibalulekileyo ezikhawulezileyo, isikhongozeli solwandle (i-FCL/LCL) see-odolo ezinkulu, kunye nezikhongozeli ezisicaba zeengqiniba ezinkulu. Onke amaxwebhu okuthumela (Uluhlu lokuPakisha, i-invoyisi yoRhwebo, iSatifikethi seMvelaphi, kunye nePakeji epheleleyo yoVavanyo) zilungiselelwe ukwenza kube lula ukususwa kwempahla kwiiprojekthi zoshishino kwihlabathi liphela.

Isicelo

Ioyile kunye neGesi (iArctic kunye neOffshore):

Iipayipi zamanzi angaphantsi kolwandle, amaqonga okuvelisa amanzi angaphandle kolwandle kwiindawo ezibandayo, kunye neenkqubo zokuqokelela amanzi angaphandle kolwandle kwiindawo ezinemozulu ebandayo.

Ushishino lweLNG (iGesi yendalo enyibilikisiweyo):

Iibhokisi ezibandayo, imigca yenkqubo yokunyibilikisa ulwelo, imigca yokudlulisa i-LNG, kunye nemibhobho yetanki yokugcina esebenza kumaqondo obushushu aphantsi.

Ukucubungula i-Cryogenic:

Izityalo zegesi zoshishino (ukwahlulwa kwe-O2, i-N2, i-Ar), izityalo ze-ethylene, kunye nemibhobho yokuthutha i-CO2.

Amandla kunye neekhemikhali:

Imigca yokucubungula kwiindawo ezikwiindawo ezibandayo kakhulu.

Ingcali kwizixhobo ezikumgangatho ophantsi:

Sinolwazi olunzulu kwiinkcukacha, uvavanyo, kunye nokuphathwa kweentsimbi zekhabhoni ezinobushushu obuphantsi, ukuqinisekisa ukuba imveliso inika ukusebenza okuqinisekisiweyo.

Ingqwalasela yoMveliso engenamthungo:

Ukuzibophelela kwethu kwimveliso engenamthungo kuqinisekisa ukuthembeka okuphezulu kwinkonzo ebalulekileyo ye-cryogenic apho iimpazamo ze-weld zingamkelekanga.

Iphakheji yeSatifikethi esiBanzi:

Sinikezela ngamaxwebhu angqongqo kakhulu kushishino, ingakumbi iiNgxelo zoVavanyo lweCharpy Impact eziqinisekisiweyo, ezibalulekileyo ekuvunyweni kobunjineli kunye nokuhlolwa kokhuseleko kwiiprojekthi ezishushu kakhulu.

Ukwenziwa ngokwezifiso okusekelwe kwiProjekthi:

Silungisa iimveliso ngokweemfuno ezithile zeprojekthi, kubandakanya ubungakanani obukhethekileyo, amaqondo obushushu ovavanyo lwempembelelo oluphuculweyo, kunye ne-NDT eyongezelelweyo, sikhonza ngokuthe ngqo abakhi be-EPC kunye nabasebenzisi bokugqibela.

Uthungelwano lweHlabathi lweZiseko eziBalulekileyo: Singamaqabane anamava kwiiprojekthi ezinkulu zamandla, siqinisekisa ukuba ezi zinto zikhethekileyo neziqinisekisiweyo zithunyelwa ngexesha elifanelekileyo kwiindawo ezikude okanye ezifuna umgudu omkhulu, zixhaswa ngamaxwebhu apheleleyo okulandelelwa kunye nomgangatho.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

Ishedyuli ye-ANSI b16.9 intshi ezingama-36 40 Butt Weld carbon...

-

I-Asme b16.9 ishedyuli yezixhobo zombhobho wentsimbi ezingama-80 ...

-

intsimbi yekhabhoni ene-degree ezingama-45 egobile i-3d bw 12.7mm WT AP...

-

Izixhobo zepayipi ze-SUS304 316 Ingqiniba yentsimbi engatyiwayo ...

-

I-ANSI B16.9 Carbon Steel Bend ene-degree ezingama-45 yokuWelda

-

I-ANSI B16.9 butt weld Pipe Fitting carbon steel ...