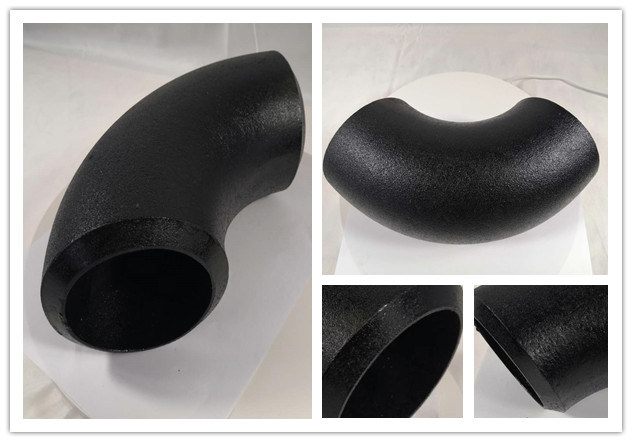

I-90 degree elbow tee reducer steel Butt weld pipe fitting elbow

Izixhobo zombhobho weld weld weld zentsimbi yekhabhoni—kuquka iingqiniba ze-90-degree, ii-tee, kunye nee-reducers—zenza isakhelo esibalulekileyo samathambo sokuqondisa, ukuhlanganisa, kunye nokuguqula ukuhamba kolwelo kwiinkqubo zombhobho zoshishino. Zenziwe ngentsimbi yekhabhoni eqinileyo ye-ASTM A234-grade, ezi zixhobo zenzelwe uqhagamshelo oluhlala luhleli, olungenamanzi ngokusebenzisa i-butt welding, zinika amandla aphezulu kunye nokuthembeka xa kuthelekiswa nezinye iindlela ze-threaded okanye ze-socket weld.

Ezi zixhobo zenziwe ngokuchanekileyo ukuze zihlangabezane nemigangatho yobukhulu be-ASME B16.9, ziqinisekisa ukulungelelaniswa ngokugqibeleleyo kunye nokuhambelana nemibhobho yeshedyuli ehambelanayo. Ingqiniba ye-90° yenza kube lula ukutshintsha indlela ngokulahlekelwa kancinci koxinzelelo, i-tee ivumela uqhagamshelo lwamasebe, kwaye i-reducer ilawula utshintsho lobubanzi bemibhobho. Yenzelwe ukuhlanganiswa okungenamthungo kwiinkqubo zoxinzelelo oluphezulu kunye nobushushu obuphezulu kumacandelo afana neoyile negesi, ukuveliswa kombane, kunye nokucutshungulwa kweekhemikhali, zibonelela ngesisombululo esithembekileyo, esingenalondolozo sokwakha iinethiwekhi zemibhobho ezihlala ixesha elide nezisebenzayo.

IIPARAMETHA ZEMVELISO

| Igama lemveliso | Ingqiniba yombhobho |

| Ubungakanani | Ingqiniba engenamthungo eyi-1/2"-36" (ingqiniba ye-SMLS), i-26"-110" idityaniswe ngomthungo. Ububanzi obukhulu bangaphandle bunokuba yi-4000mm |

| Umgangatho | I-ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, njl. |

| Ubukhulu bodonga | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS njl. |

| Isidanga | 30° 45° 60° 90° 180°, njl. |

| Irediyasi | Irediyasi ye-LR/ende/R=1.5D,SR/Irediyasi emfutshane/R=1D |

| Isiphelo | Isiphelo seBevel/BE/buttweld |

| Umphezulu | umbala wendalo, ivarnish, upende omnyama, ioyile yokulwa nomhlwa njl. |

| Izinto eziphathekayo | Intsimbi yekhabhoni:A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH njl. |

| Intsimbi yombhobho:I-ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 njl. | |

| Intsimbi ye-Cr-Mo alloy:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, njl. | |

| Isicelo | Ishishini lePetrochemical; ishishini leenqwelo moya kunye neenqwelo moya; ishishini lamayeza, umphunga wegesi; isityalo samandla; isakhiwo seenqanawa; unyango lwamanzi, njl. |

| Iingenelo | isitokhwe esilungeleyo, ixesha lokuhanjiswa ngokukhawuleza; ifumaneka kuzo zonke iisayizi, yenzelwe wena; umgangatho ophezulu |

IZIXHOBO ZEMIPAYIPI

Izixhobo zombhobho ezidityanisiweyo ngeempundu ziquka ingqiniba yombhobho wentsimbi, i-tee yombhobho wentsimbi, i-steel pipe reduer, i-steel pipe cap. Zonke ezo zixhobo zombhobho zokudityaniselwa ngeempundu, singazibonelela kunye, sinamava emveliso angaphezulu kweminyaka engama-20.

Ukuba unomdla nakwezinye izixhobo, nceda ucofe ku-LINK elandelwayo ukuze ujonge iinkcukacha.

I-PIPE TEE ISINCIPHI SOKUNCIPHISA IMIBHAWU Isiciko sepayipi I-PIPE BEND IZIXHOBO EZIQINISEKISIWEYO

I-BUTT WLDED PIPE ELBOW

Ingqiniba yentsimbi yinxenye ebalulekileyo kwinkqubo yemibhobho yokutshintsha indlela ukuhamba kolwelo. Isetyenziselwa ukudibanisa imibhobho emibini enobubanzi obufanayo okanye obahlukeneyo, nokwenza umbhobho ujike uye kwicala elithile le-45 degrees okanye i-90 degrees.

Kwi-industrial pipe elbow, uhlobo lwe-connectin end yi-butt weld, ngokwe-ANSI B16.25. I-butt weld ingachazwa njenge-butt welding, i-buttweld, kunye ne-bevel end. BW

UHLOBO LWESIBANDLA

Izinto kunye noMveliso: Izixhobo zenziwe nge-ASTM A234 WPB (intsimbi yekhabhoni eqhelekileyo) okanye ezinye iintlobo ze-alloy (WP5, WP11, njl.njl.) ukuze zisetyenziswe kumaqondo obushushu aphezulu. Zenziwa ngokusebenzisa ukwenziwa kwe-hot form (forging okanye induction bending) okanye iinkqubo zokwenza i-cold, kulandele unyango lobushushu (normalizing) ukuze kuncitshiswe uxinzelelo kunye nokubuyisela iipropati zoomatshini. Oku kuqinisekisa ulwakhiwo olufanayo lweenkozo kunye nokuqina okuphuculweyo.

Ubunjineli Bokuchaneka: Ubukhulu obubalulekileyo—obufana nombindi ukusuka esiphelweni ukuya esiphelweni (ingqiniba), umbindi ukusuka ebusweni ukuya ebusweni (i-tee), kunye nobude obupheleleyo (isinciphisi)—bucwangciswe ngomatshini ukuze bulingane ne-ASME B16.9. Imiphezulu yangaphakathi nangaphandle ithambile ukuze kuncitshiswe ukuxinana kunye nokukhukuliseka. Zonke iziphelo ze-weld zichanekile (37.5° ± 2.5°) kunye nomhlaba ohambelanayo ukuqinisekisa ukungena ngokupheleleyo ngexesha lokuxhunyelwa kunye namandla afanelekileyo ejoyinti.

Iintlobo zoYilo:

Ingqiniba engama-90°: Ifumaneka kwiLong Radius (LR, 1.5D bend radius) ukuze kuhambe kakuhle kwaye kuncitshiswe uxinzelelo, kunye neShort Radius (SR, 1D bend radius) ukuze kufakelwe indawo encinci.

I-Tee: Ii-Tee ezilinganayo zinesebe elifanayo kunye nobukhulu bokusebenza; Ii-Tee ezinciphisayo zinesebe elincinci, zivumela ukwahlula-hlula kokuhamba okanye uqhagamshelo lwezixhobo.

I-Reducer: Ii-Concentric Reducers zigcina umgca ophakathi, osetyenziswa kwimigca ethe nkqo. Ii-Eccentric Reducers zinomgca ophakathi ophakathi, obalulekileyo kwimigca yokufunxa ipompo ethe tye ukuze kuthintelwe ukwakheka kwepokotho yomoya.

Uphawu Lomgangatho: Isixhobo ngasinye siphawulwa ngokusisigxina ngomgangatho wezinto (umz., A234 WPB), ubungakanani, ishedyuli, ilogo yomenzi, kunye nenombolo yobushushu (ukuze kulandelelwe), ngokuhambelana ne-ASTM A960.

UMPHEZULU WE-ELBOW

Ukuqhuma kweSand

Emva kokwenza ubushushu, silungiselela ukuqhuma kwesanti ukuze umphezulu ucoceke kwaye uthambe.

Emva kokuqhuma kweSand, ukuze kuthintelwe ukugqwala, kufuneka upeyinte ngomnyama okanye ngeoyile yokulwa nomhlwa, i-Hot dip galvanized (HDG), i-epoxy, i-3PE, umphezulu onyamaleleyo, njl. Oko kuxhomekeke kwisicelo somthengi.

UNYANGO LOBUSHUSHU

1. Gcina isampuli yezinto ezikrwada ukuze zilandelelwe.

2. Lungiselela unyango lobushushu ngokwemigangatho emiselweyo.

UKUPHAWULA

Imisebenzi eyahlukeneyo yokumakisha, inokugoba, ipeyintwe, ibhalwe ilebhile. Okanye xa ucela. Siyamkela ukumaka iLOGO yakho.

IINKCUKACHA ZEMVELISO

Ingqiniba engama-90°: I-Long Radius (LR - 1.5D) kunye ne-Short Radius (SR - 1D) ubukhulu obuphakathi nobuso.

I-Tee: Ithe tye (Elinganayo) kwaye Inciphisa uqwalaselo.

I-Reducer: I-Concentric (iziko ezilungelelanisiweyo) kunye ne-Eccentric (iziko ezichaseneyo, ezidla ngokuba zithe tyaba phezulu kwimigca yokufunxa ipompo).

Ukulungiselela Isiphelo: Iziphelo ezigobileyo zokuwelda, zihlala zine-bevel engama-37.5° kunye nomhlaba oyi-1.6mm.

Unyango Lomphezulu: Umnyama (isikali semill), ogqunywe ngesanti, okanye opeyintwe (iprimer) njengoko kufuneka.

UVAVANYO

1. Ubungakanani bokulinganisa, konke kuxhomekeke ekunyamezeleni okuqhelekileyo.

2. Ukunyamezelana kobukhulu: +/- 12.5%, okanye ngokwesicelo sakho

3. I-PMI

4. Uvavanyo lwe-MT, UT, X-ray

5. Yamkela uhlolo lomntu wesithathu

6. Nikeza isiqinisekiso se-MTC, EN10204 3.1/3.2

UKUPAKISHA NOKUTHUMELA

Ukupakishwa: Izixhobo zipakishwa ngononophelo ukuthintela umonakalo ngexesha lokuhamba. Ukhuseleko oluqhelekileyo luquka ukugqunywa ngeoyile yokulwa nomhlwa okanye i-VCI (iVapor Corrosion Inhibitor) kunye nokugqunywa ngakunye ngeplastiki okanye iphepha elingangeni manzi. Iziphelo ezigobileyo zikhuselwe ngeplastiki okanye intsimbi ukuze kugcinwe umphezulu wokuwelda. Kwiiodolo ezinkulu, izixhobo ziyapakishwa kwaye ziqiniswe ngemitya yentsimbi, emva koko zigqunywe nge-shrink wrap. Izixhobo ezinkulu okanye ezinzima zifakwa kwiibhokisi zomthi ezenziwe ngokwezifiso ezine-bracing yangaphakathi.

Ukuphawula kunye namaxwebhu: Iphakheji nganye ibhalwe inkcazo yemveliso, ubungakanani, izinto ezisetyenzisiweyo, ubungakanani, kunye nenombolo ye-PO. Amaxwebhu okuthumela aquka uluhlu oluneenkcukacha zokupakisha, i-invoyisi yorhwebo, kunye nezatifikethi zezinto ezisetyenzisiweyo.

Ukuthunyelwa: Sinikezela ngezisombululo zokuthunyelwa eziguquguqukayo ngesikhongozeli saselwandle (i-FCL/LCL), ukuthunyelwa ngenqwelomoya, okanye ukuhanjiswa komhlaba. Kwimithwalo yeprojekthi, sisebenzisana nabathumeli bemithwalo abakhethekileyo ukuze baphathe izixhobo ezinkulu, ukuqinisekisa ukuhanjiswa okukhuselekileyo nangexesha elifanelekileyo kwiindawo zehlabathi.

Izicelo Ezibanzi Zemizi-mveliso: Ezi zixhobo zokuwelda ezingasemva zizinto ezibalulekileyo kumacandelo amaninzi:

- Ioyile neGesi: Iipayipi zaselunxwemeni/elunxwemeni, iipayipi zenkqubo yokucocisa, ii-manifolds zemithombo yamanzi, kunye nezikhululo zecompressor.

- Ukuveliswa koMbane: Imigca ephambili yomphunga kunye namanzi okuhambisa amanzi kwizityalo ezishushu, iinkqubo zamanzi okupholisa, kunye nemibhobho yegesi yepetroli.

- Izityalo zeKhemikhali kunye nePetrochemical: Iintambo zokutya zeReactor, imibhobho ye-distillation column, uqhagamshelo lwe-heat exchanger, kunye neenkqubo zokuphatha ulwelo olubolayo.

- Unyango kunye noSasazo lwaManzi: Iintloko zokukhupha amanzi kwimpompo, imibhobho yesihluzo, kunye neenjini zokuhambisa amanzi ezinobubanzi obukhulu.

- Ukwakha iinqanawa kunye nobunjineli bolwandle: Iipayipi zegumbi leenjini, iinkqubo ze-ballast, kunye nemigca yokuhambisa imithwalo.

Iingenelo zethu zoLwakhiwo lweMveliso kunye noNikezelo:

- Uluhlu Olupheleleyo kunye nokuFumaneka: Sigcina uluhlu olupheleleyo lobukhulu obuqhelekileyo kunye neeshedyuli kwisinyithi sekhabhoni, siqinisekisa ukuhanjiswa ngokukhawuleza kwiiprojekthi eziqhelekileyo kunye nokuvalwa kolondolozo.

- Ubungcali boBugcisa kunye nokuLungiselela: Iqela lethu lobunjineli lixhasa iimfuno ezingezizo ezisemgangathweni, kubandakanya ubungakanani obukhethekileyo (ngaphaya kwama-48"), ubukhulu bodonga obukhethekileyo, amalungiselelo akhethekileyo, okanye izixhobo ezenziwe ngokwemigangatho ethile yobukhulu bomthengi (umz., i-JIS, i-DIN).

- Uqinisekiso loMgangatho ukususela ekuqaleni ukuya ekugqibeleni: Sisebenzisa ulawulo olungqongqo lomgangatho kuzo zonke izigaba—ukusuka ekuhlolweni kwezinto eziluhlaza ukuya ekuqinisekisweni kobukhulu bokugqibela—siqinisekisa ukuba ukufakwa ngakunye kuhlangabezana nemigangatho ephezulu yokuthembeka nokusebenza.

- Uthungelwano lweHlabathi oluSebenza ngexabiso eliphantsi: Njengomvelisi othe ngqo onamava amaninzi okuthumela ngaphandle, siphucula iindlela zokupakisha nezokuthumela ukuze sinikezele ngokuhanjiswa okuthembekileyo nokungenazindleko kwiindawo zomsebenzi kwihlabathi liphela, okuxhaswa ngamaxwebhu apheleleyo okususwa kwempahla ngaphandle kokuphazamiseka.

- Ukuthembeka kwexesha elide: Izixhobo zethu zenzelwe ukuqina nokusebenza ixesha elide, kunciphisa iindleko zokugcinwa kunye nexesha lokungasebenzi kubathengi bethu, nto leyo ebenza babe lukhetho oluthembekileyo kwiiprojekthi ezibalulekileyo zeziseko zophuhliso kwihlabathi liphela.

Izixhobo zokufaka iipayipi zizinto ezibalulekileyo kwinkqubo yokuhambisa iipayipi, ezisetyenziselwa ukunxibelelana, ukuqondisa kwenye indawo, ukuphambukisa, ukutshintsha ubungakanani, ukuvala okanye ukulawula ukuhamba kwamanzi. Zisetyenziswa kakhulu kwiindawo ezifana nokwakha, ishishini, amandla kunye neenkonzo zikamasipala.

Imisebenzi ephambili:Ingenza imisebenzi efana nokudibanisa imibhobho, ukutshintsha indlela yokuhamba kwayo, ukwahlula nokudibanisa ukuhamba kwayo, ukulungisa ububanzi bemibhobho, ukuvala imibhobho, ukulawula nokulawula.

Ububanzi besicelo:

- Ulwakhiwo lwamanzi kunye nemibhobho yamanzi:Iingqiniba zePVC kunye nee-PPR tris zisetyenziselwa iinethiwekhi zemibhobho yamanzi.

- Imibhobho yemizi-mveliso:Iiflange zentsimbi engenasici kunye neengqiniba zentsimbi ye-alloy zisetyenziselwa ukuthutha izixhobo zamakhemikhali.

- Uthutho lwamandla:Izixhobo zokufaka iipayipi zentsimbi ezinoxinzelelo oluphezulu zisetyenziswa kwimibhobho yeoyile negesi.

- I-HVAC (Ukufudumeza, Ukungenisa umoya, kunye ne-Air Conditioning):Izixhobo zombhobho wekopolo zisetyenziselwa ukudibanisa imibhobho yefriji, kwaye amalungu aguquguqukayo asetyenziselwa ukunciphisa ukungcangcazela.

- Ukunkcenkceshela kwezolimo:Izihlanganisi ezikhawulezayo zenza kube lula ukuhlanganiswa nokuqhekeka kweenkqubo zokunkcenkceshela izitshizi.

-

I-A234WPB ANSI B16.9 Pipe Fitting Elbow Alloy Ste ...

-

I-ANSI B16.9 butt weld Pipe Fitting carbon steel ...

-

I-intshi ezi-8 zentsimbi engagqwaliyo isiciko sombhobho wokuphela kwesiciko ...

-

I-ANSI B16.9 intsimbi engatyiwayo ene-butt weld ye-45 degree ...

-

sch80 ss316 intsimbi engagqwaliyo Butt Weld Eccentri ...

-

I-SUS304 316 Stainless Steel Butt-Weld Fittings B...